Which CO2 Laser Cutting Machine is the Best?

Your leather, plastic, and other similar non-metal processing need to be equipped with the best co2 laser cutting machines that can respond positively to the various demands in use. Therefore, the best choice for this machine can be one of the many CO2 machines from GWEIKE.

Today we will clarify the best co2 laser cutting machines you need to buy as soon as possible.

Our selection of the best co2 laser cutting machines

- Best-selling: STORM600 Laser Engraving Machine

- Most stable performance: LC1390N Laser Cutting Machine

- Largest working area: LC1325D Laser Cutting Machine

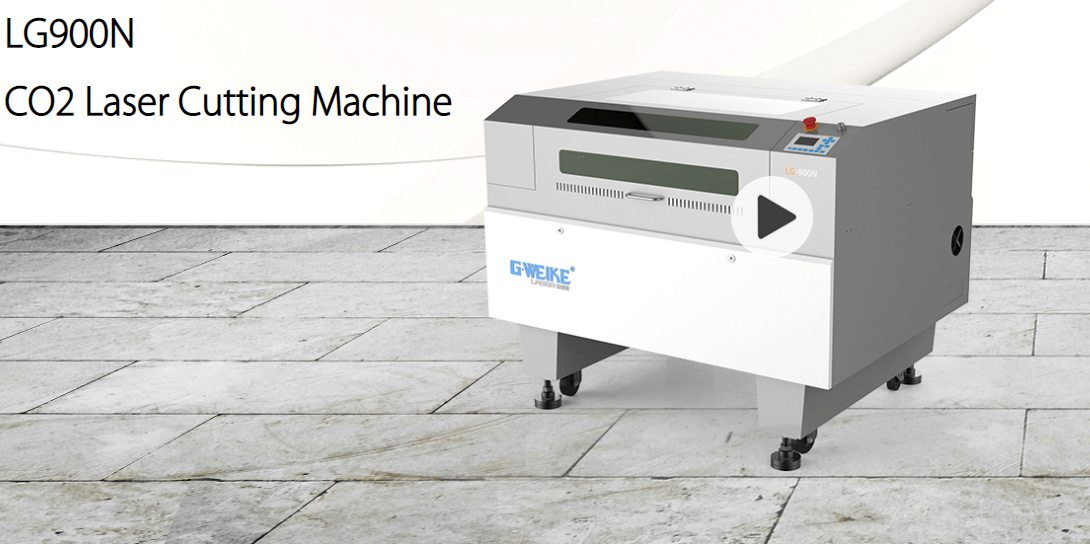

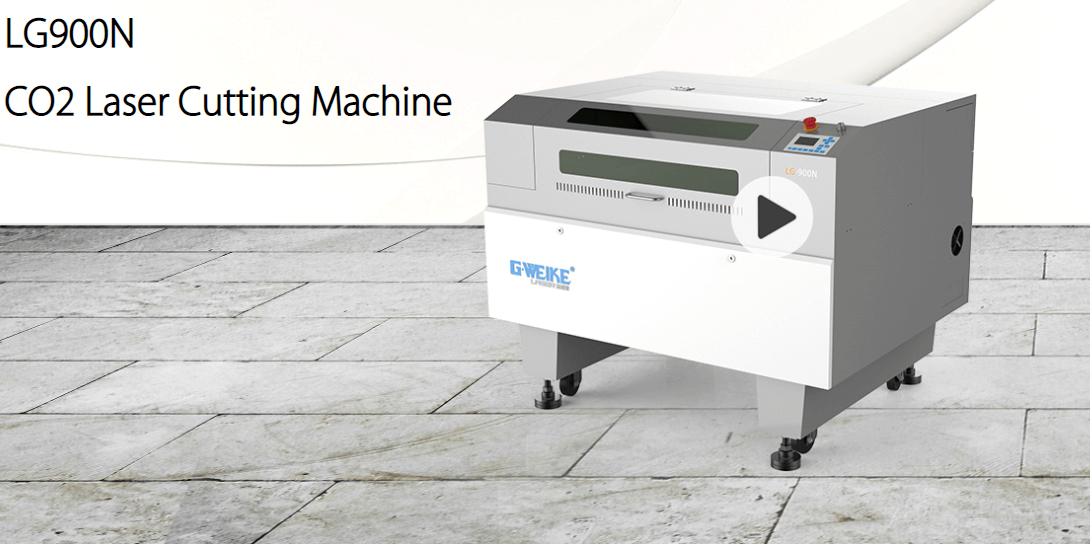

- Best value for money: LG900N Laser Engraving Machine

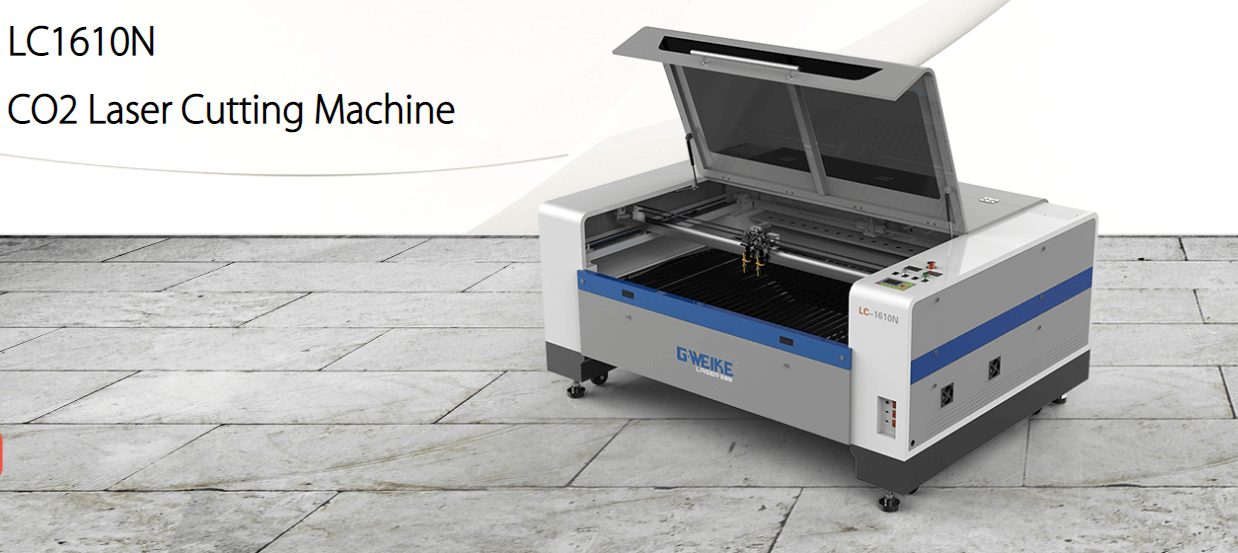

- Best Efficiency: LC1610N CO2 Laser Cutting Machine

- The most intelligent: LG6040N Laser Engraving Machine

Best CO2 Laser Cutting Machines

Best-selling: STORM600 Laser Engraving Machine

Technical Parameters

| Laser Power | 40w 60w |

|---|---|

| Engraving Area | 600mm x 400mm |

| Worktable | Manual up-down table |

| Whole Machine Size | 950mm x 740mm x 450mm |

| Engraving Speed | 0-48,000mm/min |

| Resetting Positioning Accuracy | ±0.05mm |

| Working Voltage | AC 110-220V ±10%, 50-60Hz |

| Gross Power | <1000w |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Minimum Shaping Character | English 1x1mm |

| Graphic Format Supported | BMP, PLT, DST, DXP, and AI |

| Driving System | stepper |

| Cooling Mode | Water-cooling and protection system |

| Auxiliary Equipments | Exhaust-fans, air-exhaust pipe |

| Controlling Software | DSP control system |

| Compatible Software | CorelDraw AutoCAD Photoshop |

Features

- U.S II-VI Optical Lenses

Faster transmission of light beams. Ensures efficient machine operation. - Motor

Less noise, faster, and more accurate. - Fan

Support independent fan control - Dual platform

Provide honeycomb and blade platform for cutting and engraving - Smoke filtration

The generated fumes are filtered through three levels of filter bags, HEPA, and activated carbon adsorption to ensure that the emitted fumes are pollution-free.

Cons

- Manual focus

Most stable performance: LC1390N Laser Cutting Machine

Technical Parameters

| Laser power | 80W 100W 130W 150W 200W (optional) |

|---|---|

| Cutting Area | 1300mm x 900mm |

| Whole Machine Size | 1820* 1310* 1070mm |

| Cutting Speed | 0 - 24,000mm/min |

| Resetting Positioning Accuracy | ±0.05mm |

| Working Voltage | AC 110 -220V±10%, 50-60Hz |

| Gross Power | <1,500W |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Minimum Shaping Character | English 1x1mm |

| Work Table | 18cm lift platform |

| Driving System | Stepper |

| Cooling Mode | Water-cooling and protection system |

| Auxiliary Equipments | Exhaust-fans, air-exhaust pipe |

| Controlling Software | DSP control system |

| Compatible Software | CorelDraw AutoCAD Photoshop |

Features

- Electronic lifting

Automatic lifting of the table up to 20cm - Auto-focusing

Autofocus, higher precision. - Four-sided feeding

Four-sided feeding system for maximum size cutting and engraving of materials. - Hiwin Linear Guideway

Rolling guides reduces wear and tear for higher positioning accuracy. - RECI laser tube

Longer life and faster cutting with a focused beam. - WIFI control

One PC can control more than one machine, which means higher efficiency - Advanced motor

Low noise and good processing performance

Cons

- More expensive, but worth the price

Largest working area: LC1325D Laser Cutting Machine

Technical Parameters

| Laser Power | 60W 80W 100W 130W 150W (Optional) |

|---|---|

| Cutting Area | 1300mm x2500mm |

| Whole Machine Size | 3000* 1600* 990mm |

| Cutting Speed | 0 -24000mm/min |

| Resetting Positioning Accuracy | ±0.1mm |

| Working Voltage | AC 110-220V ±10%,50 60Hz |

| Gross Power | <1,500W |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Minimum Shaping Character | English 1x1mm |

| Graphic Format Supported | BMP, PLT, DST, DXP, and AI |

| Driving System | Stepper |

| Cooling Mode | Water-cooling and protection system |

Features

- Hiwin Linear Guideway

High positioning accuracy can maintain higher accuracy for a long time. - RECI laser tube

Concentrated beam, good quality, and high speed with higher working efficiency. - Extra large working table

Large working table, you can engrave the area you need at once

Cons

- An open plan machine needs to pay attention to safety when working.

Best value for money: LG900N Laser Engraving Machine

Technical Parameters

| Laser Power | 60W 80w (optional) |

|---|---|

| Working Area | 900mm×600mm |

| Cutting Speed | 0-30000mm/m |

| Work Platform | Crawler type work platform |

| Working Speed | Adjustable |

| Position Accuracy | ±0.5mm |

| Control System | DSP control system in USB mode |

| Cooling Mode | Constant temperature water-cooling |

| Working Voltage | AC220V±5% / 50HZ |

| Graphic Format Supported | AI BMP PLT DXF DST |

| Operating Temperature | 0°C-45°C |

| Operating Humidity | Free of condensed water |

Features

- Hiwin Linear Guideway

High positioning accuracy can maintain higher accuracy for a long time. - RECI laser tube

Concentrated beam, good quality, and high speed with higher working efficiency. - Extra large working table

Large working table, you can engrave the area you need at once

Cons

- An open plan machine needs to pay attention to safety when working.

Best value for money: LG900N Laser Engraving Machine

Technical Parameters

| Laser Power | 60W 80w (optional) |

|---|---|

| Working Area | 900mm×600mm |

| Cutting Speed | 0-30000mm/m |

| Work Platform | Crawler type work platform |

| Working Speed | Adjustable |

| Position Accuracy | ±0.5mm |

| Control System | DSP control system in USB mode |

| Cooling Mode | Constant temperature water-cooling |

| Working Voltage | AC220V±5% / 50HZ |

| Graphic Format Supported | AI BMP PLT DXF DST |

| Operating Temperature | 0°C-45°C |

| Operating Humidity | Free of condensed water |

Features

- Electronic lifting

The machine can automatically adjust the working table to meet the needs of cutting different thicknesses of materials. Lifting height up to 20cm. - Automatic Focusing

Auto-focus makes it easy and fast to focus the laser head. No need to adjust the focus manually, saving time and higher accuracy. - WiFi

Engineers can remotely control the computer and machine to help you adjust and solve problems in real time. - Cost-effective

Affordable price with full features

Cons

- Unable to pass the material on all sides

Best Efficiency: LC1610N CO2 Laser Cutting Machine

Technical Parameters

| Laser Power | 80w 100w 130W (optional) |

|---|---|

| Working Area | 1600mm×1000mm |

| Cutting Speed | 0-36000mm/m |

| Work Platform | Crawler type work platform |

| Working Speed | Adjustable |

| Position Accuracy | ±0.1mm |

| Control System | DSP DSP control system in USB mode |

| Cooling Mode | Constant temperature water-cooling |

| Working Voltage | AC220V±5% / 50HZ |

| Graphic Format Supported | AI BMP PLT DXF DST |

| Operating Temperature | 0°C-40°C |

| Operating Humidity | Free of condensed water |

| Gross Power | ≤2000W |

Features

- Automatic lifting

Automatic lifting and lowering of the table to improve efficiency - Automatic Focusing

Automatically adjusts the focus of the cutting head for more efficient punching and cutting. - Hiwin guide rail

Wear-resistant and smooth for high-speed operation

The most intelligent: LG6040N Laser Engraving Machine

Technical Parameters

| Laser Power | 40W 60W 80W (optional) |

|---|---|

| Engraving Area | 600mm x 400mm |

| Worktable | Motorized up down table |

| Whole Machine Size | 1360*850*950mm |

| Engraving Speed | 0-36,000mm/min |

| Resetting Positioning Accuracy | ±0.05mm |

| Working Voltage | AC 110-220V±10%,50-60Hz |

| Gross Power | <1000W |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Minimum Shaping Character | English 1x1mm |

| Graphic Format Supported | BMP, PLT, DST, DXP, and AI |

| Driving System | Stepper |

| Cooling Mode | Water-cooling and protection system |

Feature

- Automatic lifting

- Automatic focus

- Small size and space saving

FAQ

What is co2 laser engraving machine?

A co2 laser engraving machine is a machine that uses an electric current to produce an invisible beam of light to cut non-metallic materials quickly and accurately.

How to choose a co2 laser cutting machine

In the co2 laser marking machine selection process, we need to consider some considerations to help us choose a better machine. The following points we need to pay attention to in the selection process.

- Cutting materials

The co2 laser marking machine is more suitable for cutting non-metal materials like wood, plastic, leather, etc. If you want to cut metal, it is recommended to change the cutting machine. Please read Gweike's Best Metal Laser Cutting Machine. - Cutting type

If you need to engrave or cut very complicated patterns, you must pick a co2 laser cutting machine with high precision. - Price

The range of machines you choose depends greatly on your budget, and the price of a co2 laser cutting machine can vary by tens of thousands of dollars. So make sure you have a good budget before choosing one. - Size

This includes the size of the table and the machine. Choosing a larger table can greatly improve your work efficiency if you need to engrave large material areas frequently. If you have a small site reserved for machine placement, you need to pay extra attention to the size of the machine when purchasing. - Filter fumes

Very few non-metallic materials in the cutting process will produce toxic gases. Suppose you cut materials that belong to the category of easy to produce toxic gases. In that case, you need to pay extra attention to the machine when purchasing the filtering function. In serious cases, you must do a good job of personal protection or buy a special filter cabinet.

How long does a CO2 laser engraving machine last?

The life span of a co2 laser cutting machine is about 20 years. This is because it only cuts metal for a short time and is maintained regularly after use. This will help to extend the life of the machine.

What to pay attention to when using the machine

- Do not touch the table and laser head while the machine is working

- Do not touch the cutting material after the machine has stopped

- Wear goggles when working with open type laser cutting machines

- Use in a well-ventilated environment as much as possible

What metals can be engraved with a CO2 laser

The Co2 laser is not completely incapable of engraving & cutting metals. Below, we list some metals that can cut with the co2 laser.

*Can't cut continuously for long periods

- Stainless steel: You can engrave many stainless steel materials, including medical, 2D codes, etc., that require high image accuracy.

- Brass: engraving on heat-treated brass will produce better engraving results

- Copper: You can engrave on copper, but it requires sufficient experience. Because copper is soft, it is not well controlled during engraving.

- Aluminum Oxide: Low power and low speed are required when carving aluminum oxide. Otherwise, it will damage the material.

- Carbon steel: When carving carbon steel, you need to get a chemical coating on the surface before cutting it.

Final Thoughts

Finding a CO2 laser engraver machine for your factory for industrial use takes work. I also hope that this article has given you some reference. If you still haven't thought about it, I suggest you go for the LC1390N because this machine has been around for a long time. It has yet to be eliminated because of its various features and the price, which is more suitable and loved by customers.