A Practical Guide to Laser Rust Removal Machine for Beginners

Laser rust removal machines provide a cost effective, non-polluting, and efficient solution for rust removal. A laser cleaning machine can immediately clean rusted or corroded parts without damaging the metal surface.

This article will help you understand rust removal machines' various aspects.

- What is a laser rust removal machine?

- Application of rust removal laser machine?

- What are the ways to remove rust?

- Rust removal laser machine cleaning methods

- Laser rust removal machine recommendation

- How to choose the suitable laser cleaning machine

- What is the price of a laser rust removal machine

- Where can I buy a clean laser machine?

- Conclusion

What is a laser rust removal machine?

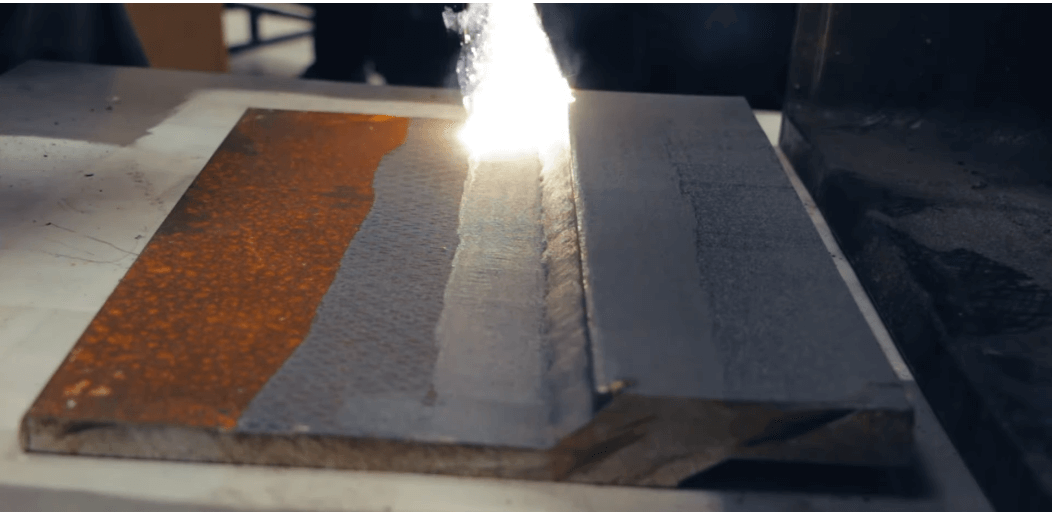

The rust removal laser machine is a machine that uses a laser to clean metal rust. It is currently the fastest way to clean and remove rust. The cleaning process does not require chemical reagents, water, or other auxiliary materials. You can use it to effectively remove oxides, oil, paint, coatings, rust, and other stains from metal surfaces, and it is very safe without damaging the metal underneath the surface. It also comes with a portable laser rust removal gun, making the process very flexible.

Application of laser rust removal machine?

Laser clean machines are most commonly used in the following areas.

- Welding industry

Many advanced welding machines are now equipped with a clean laser head designed to improve the welded parts' quality considerably. We can remove the melt produced immediately after welding. This results in smaller weld seams and a longer life. - Pre-coating

Before welding the metal, we need to clean the surface first. This does not mean cleaning with water but using a laser to remove the oxides from the metal surface. A clean surface is then painted to achieve absolute corrosion protection. - Mold cleaning

The laser machine not only cleans metal but can also use for dirty tires, food molds, and other products. - Precision parts

For some super-precise parts, it can be difficult to remove impurities from small crevices by hand. Clean laser machines do not have to worry about this, as the laser is invisible and can easily reach the deepest part of the part and clean out the impurities, for example, in many industries such as aviation and marine repair. - Heritage conservation

The laser rust remover machine is a good choice for repairing and cleaning many cultural relics and ancient buildings.

What are the ways to remove rust?

Metal is used in a wide range of industries, and rusting is a very common problem. For rusted metals, we must take measures to treat them. Otherwise, rust will reduce the life of the metal. There are many methods of rust removal for rusty metals. The following are common.

Manual rust removal

Tools:

- Steel brushes

- Scrapers

- A Wire Wheel

- A Rust Stripper Disk

Manual rust removal is mainly achieved by physical vibration or by scraping the rusted metal surface with a machine. Either way, metal will scratch the surface to varying degrees. The results are not ideal, and we can only remove loose or thin layers of rust. It is difficult to remove ancient rust stains.

Laser rust removal

Laser cleaning is very effective and does not damage the texture of the metal surface. However, you will need to determine the exact machine size to buy depending on the area you are cleaning.

Chemical Rust Removal

Apply a chemical reagent to a rusty metal surface and wait until the solution reacts chemically with the rust, which will dissolve and come off. This method is only suitable for removing small products of simple design rather than for large or precision machines.

- We must wash off the chemicals with water after removing the rust. Otherwise, it will continue to corrode the metal

- Wear gloves when applying or spraying the solvent, and be careful not to get the solution on your skin.

Pros of the laser rust removal machine cleaning process

- Wide range of materials that can be cleaned, e.g., metal, rubber, etc.

- A high degree of automation, very easy to use

- Low operating and maintenance costs

- No contamination during the cleaning process, and no chemical reagents required

- High speed and efficiency

- No change in the texture of the metal surface

- Long service life and safe, non-contact cleaning operation

Cons

- Safety training required before the use

- Cannot clean oversized areas quickly

Laser rust removing machine cleaning methods

- Hand-held: Suitable for small areas and easy to operate by hand

- Semi-automatic: The scanning head is mounted on a servo motor driven spindle, saving workforce compared to traditional manual cleaning.

- Fully automatic: Direct computer control with automatic batch cleaning by setting parameters.

Laser rust removal machine recommendation

Handheld Laser Welding & Cleaning Machine

The rust removal machine is available in 2 models, you can use it as a laser cleaning machine or a laser welding machine. You save money by buying two processes for the cost of one machine. And the 1000w laser rust removal gun can meet most customers' cleaning requirements. The rust removal machine is highly efficient at removing rust and can clean an area of approximately 800 square meters per hour.

The laser rust removal machine has an intelligent touchscreen design with quick and easy-click settings, real-time fault reading, feedback, and alarm functions. And you can also save your cleaning parameters for the next use and select them directly from the computer.

The laser rust removal gun is designed with double protection windows to protect the focusing mirror from dust contamination during laser cleaning machine operation.

Laser cleaning machine parameters

| Laser power | 1000W 1500W 2000W (optional) |

|---|---|

| Laser wave length | 1064nm |

| Fiber length | Standard10M / Maximum 15M |

| W0 | 0~120 mm/s |

| Cooling Chiller | Industrial water chiller |

| Working environment temperature range | 15~35 ℃ |

| Welding thickness recommendations | 0.5-3mm |

| working voltage | 220 V |

| Cleaning parameters | Cleaning width: 0-80mm |

| Focus height: 600mm |

How does the Clean laser machine work?

The main principle of the Clean laser machine is that the laser head emits a specific wavelength of light onto the material's surface, causing the rust to burn instantly. The air pump then absorbs the resulting particles instantly and discharges them through the exhaust pipe to the outside, effectively avoiding environmental pollution. The next step is how the laser cleaning machine works as follows:

- Step 1: Switch on the machine

After switching on the machine, the object to be cleaned is placed within the working range of the laser gun. - Step 2: Set the parameters

The infrared light is then applied to the surface containing the dirt to remove the rust. - Step 3: Absorption of light energy

The impurities absorb the light energy and convert it into heat, rapidly heating up and allowing the burning material to leave the surface. - Step 4: Exhaust fumes

The fan quickly absorbs the soot produced and then ducts it outside. You can also purchase a filter cabinet so that the absorbed gases are filtered and discharged outdoors more environmentally friendly.

How to choose the suitable laser cleaning machine

Before buying a laser cleaning machine, refer to the one I recommended above. Because it is a welding and cleaning machine, you can use both processes for the price of one machine. Of course, if you want to buy another laser rust removal machine, you can refer to the following:

- Safety

Before you buy the machine, you need to check the safety level of the machine. If it is a Class IV machine, you must take personal precautions when operating it. It is important to check the safety rating of the machine as it can cause radiation to our skin if the rating is too high. - Power

If you need to remove dangerous coatings or corrosive metals regularly, choosing a machine with more power is best. - Cleaning machine modes

Cleaning machine modes are generally divided into single mode and multi-mode. The multi-mode laser is highly efficient and suitable for dealing with large areas of corrosion. - Fibre optic cable length

The length of the fiber optic cable is crucial to your future machine operation. Longer cables have the effect of reducing the laser pulse capacity and causing energy loss.

What is the price of a laser rust removal machine

| Clean laser machine power | Price |

|---|---|

| 1000w | ≥$10000 |

| 1500w | ≥$13000 |

| 2000w | ≥$16000 |

The above prices are taken from Amazon's product listings (for reference only). However, the cost of the machine is directly related to the power. Generally, the higher power, the higher price.

Where can I buy a clean laser machine?

Gweike is a brand that specializes in laser rust removal machines. You can trust us completely when you place an order with us. Our laser systems are available for most industries. And only quality and service are guaranteed. Of course, if you want to choose another brand, I recommend choosing some of the more well-known brand companies. The price of a cleaning machine is reasonable. Although the big brands of rust removal laser machines are not necessarily the best, our after-sales service is guaranteed. If you have any after-sales problems with your machine, you will be able to contact us quickly and negotiate a solution.

Conclusion

The laser rust removal machine is safe and simple to operate. It is an effective solution for daily cleaning oil, rust, coatings, etc. We hope the above will help you. You can consult our online customer service directly if you have any other questions.