What is 3-D 5-axis Laser Cutter

The 3-D 5-Axis laser cutter is a late starter laser machine, which you may need to learn more about as I did initially. It had developed until the last few years when it became increasingly functional and well-known. As I have researched it, I have found it to be a powerful and flexible laser cutter.

I will now talk more about the working principle and features of the 3-D 5-axis laser cutter.

The working mechanism of the 3D 5-axis laser cutter

Compared to a standard cutting machine, the essential feature of a 5-axis laser cutting machine is that it supports 360° rotation of the laser head. You can achieve curved cuts. It is mainly through 3D constantly adjusting the direction of the cutting head, which then always remains perpendicular to the cutting surface. For the actual cutting, you need to use the software to model the part in 3D first and then import it into the system to generate the cutting path.

It would help if you constantly made manual adjustments according to the part's features to avoid collisions between the cutting head and the material during the cutting process. Generally, the laser head comes with collision protection to automatically dodge uneven bumps or details not designed in the modeling.

Features and benefits of the 3D 5-axis laser cutter

Laser cutting features:

The most important feature of the 3D 5-axis laser cutter is that it supports 360° rotational cutting, which is ideal for cutting three-dimensional sheet metal materials.

Using a CNC program, you can model it in the design software and then cut any sheet metal shape.

Pros:

- Capable of cutting a wide range of shapes

- Like fiber-optic cutting machines, it has high cutting accuracy

- It can replace the traditional irregular sheet metal cutting process, is easy to operate, and has a fast cutting speed

- High production efficiency, resulting in significant savings in production time and costs

- The 3D 5-axis laser cutter is also non-contact, noise-free and loss-free

3D 5-axis laser cutter recommended

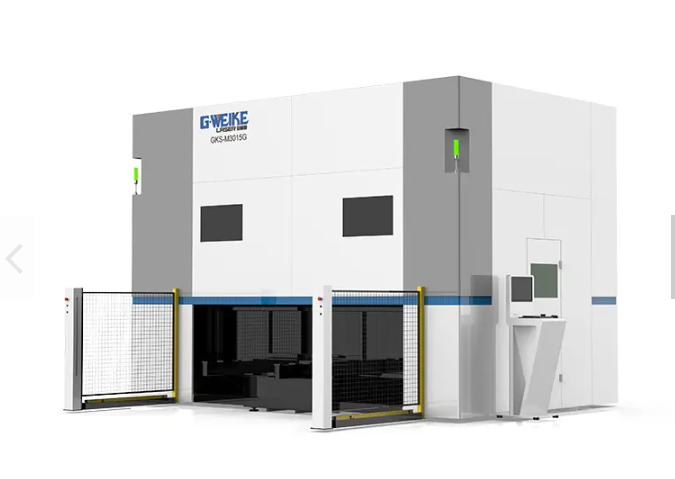

3D 5-Axis CNC Fiber Laser Cutting Machine

| 3D 5-axis laser cutter | GKS-M3015G |

|---|---|

| Power | 3000w |

| Cutting Area | 1500mm*3000mm |

| Weight | 7000 KG |

| Cutting Speed | 100m/min |

| Acceleration | 10m/s² |

| Repeat positioning accuracy | ±0.03mm |

| Maximum load | 350KG |

- Highly efficient: cutting time of a single B-pillar is controlled within the 50s

- Stable: 7*24h continuous operation, fully compatible with industrial production

- Good quality: all core components are made of international brands, for instance, IPG laser source, Han li water chiller, etc.

- Safer: all designs and components follow CE/CDRH standards and meet the safety standards of almost all industries.

- Lower energy consumption: 60% lower energy consumption compared to CO2 laser cutters of the same power

- Low cost: no wear and tear at the end of the machine's life, only simple routine maintenance required, and low running prices. The cost of operation is down,

- 360° rotating cutter for more stable cutting without adjustment

Applications of the 3D 5-axis laser cutter

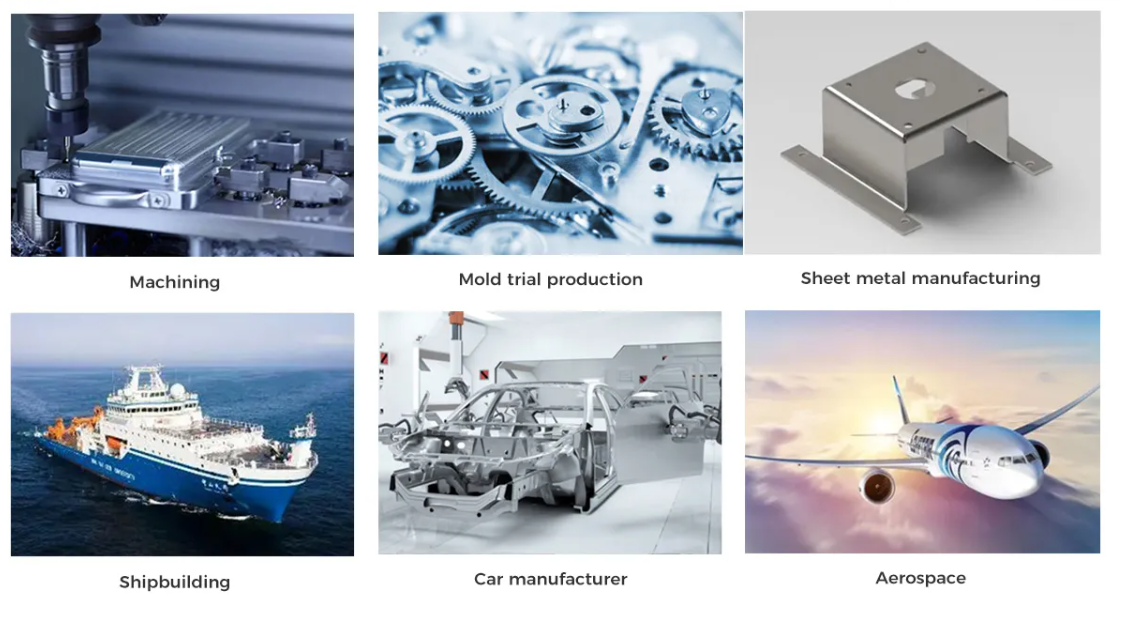

As 3D 5-axis technology continues to improve, it is now used in various industries such as carbon steel, stainless steel, aluminum, iron, and copper. We commonly see 3D 5-axis laser cutters in aerospace, machinery and equipment, home appliances, and other industries.

Difference between a 3 axis and 5 axis laser cutting machine

The fundamental difference between 3 axis vs 5 axis is the number of axes used to machine the workpiece. Although both are used for high-precision, automated precision machining, there are differences. Let's find out more together!

3 axis laser cutter

The 3 axis laser cutter cuts from front to back and left to right along the X, Y and Z axes. 3 axis laser is suitable for precision cutting of flat geometries. This is the most common type of machine used by many sheet metal fabricators. The 3 axis laser cutter is the best choice for cutting regular sheet metal.

Its disadvantage is that it can only cut vertically. For unconventional, complex, and unevenly shaped parts, constant parameter updating and repositioning is required, and the results may need to be more satisfactory.

5 axis laser machine

In contrast to the 3 axis, the 5 axis laser machine adds the A and B axes around the selection and the X, Y and Z axes. This means that the laser head of the 5 axis laser machine can be angled to cut, and complex shapes of collars can enter the cutting path into the computer and cut without problems.

The 5 axis laser machine is ideally suited for cutting irregularly shaped and complex workpieces.