Difference Between UV, CO2 and Fiber Laser Marking Machine

Laser marking machines can easily handle many high-precision markings, and this advanced technology is of great help to hospitals and industries that require high-precision engraving.

You have noticed many types of laser marking machines, which can be roughly divided into 3 categories: UV, CO2 and fiber laser marking machines. Do you know what the differences are between them?

Let's learn more about the basics of laser marking machines!

What is a Fiber laser vs CO2 laser vs UV laser

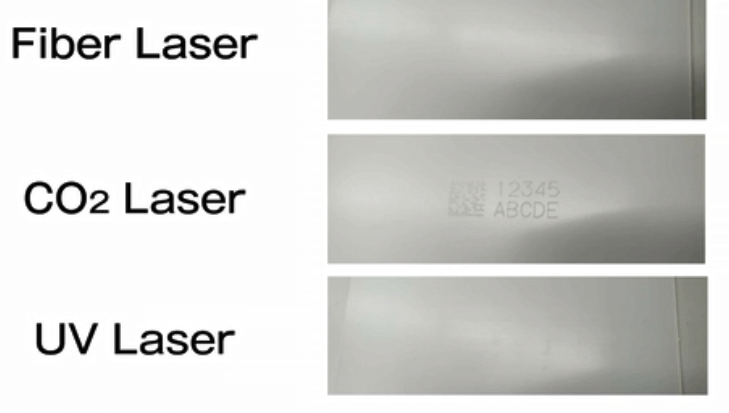

Image by keyence

The fundamental difference between Fiber, CO2 and UV laser marking machines is that the lasers work on different principles and produce different wavelengths.

Metal and non-metal materials do not absorb wavelengths similarly, so different types of laser marking machines are suitable for different applications.

Read more about what fiber, CO2 and UV laser marking machines are and their characteristics.

What is a Fiber laser marking machine

A fiber laser marking machine is an IR laser with a wavelength of 1064nm. Fiber laser marking machine is mainly used to mark brass, stainless steel, aluminum, iron and other materials. The high-power fiber laser marker is suitable for engraving and annealing and some people also use the fiber laser marking machine for rust removal.

The special fiber core and doping elements in the fiber laser make the focal diameter of the laser beam tiny. For all the same power, the fiber laser has the most powerful laser of the three, about 100 times more powerful than the CO2 laser.

The high-intensity laser energy produced by the fiber laser marking machine makes it the most suitable type of marking machine for marking metals.

The downside is that it is expensive, even though the fiber laser lasts 15 times longer than a CO2 laser and 6 times longer than a diode laser. However, desktop laser marking machines are now available for sale, making them affordable for many poorer people.

What is a CO2 laser marking machine

The CO2 laser marking machine has a wavelength of 10.6μm, which is infrared. Although it is not good at marking metals, the CO2 laser is suitable for marking non-metallic materials such as leather, fabric, wood, acrylic, marble and other non-metallic materials.

CO2 lasers are suitable for small businesses or start-ups because they are fast and can be used at higher power levels. The CO2 laser marking machine is also very easy for marking on clear acrylic and glass.At the same time, the CO2 laser marking machine is less expensive, with the same power. The price is only about one-third of that of the fiber laser.

The disadvantage of the CO2 laser tube is that it has a short life span, normally around 8,000-10,000h, and needs to be replaced once more. Replacing the laser tube costs around $200-$500 each time.

What is a UV laser marking machine

The UV laser marking machine uses a non-linear crystal to reduce the wavelength to 355 nm gradually. UV laser marking machines are suitable for marking all non-metals and some metals. Unlike CO2 and fiber laser, it does not allow for deep marking. The laser beam formation process requires a large amount of heat, so the power of the UV laser is low, usually below 10w. The UV laser is suitable for small marking applications with little damage to the product, especially in the organic and plastic marking industries.

Also, the fiber laser marking machine on metal may be less detailed than the UV laser. So I don't recommend that small businesses buy UV laser marking machines.

Fiber vs CO2 vs UV laser marking

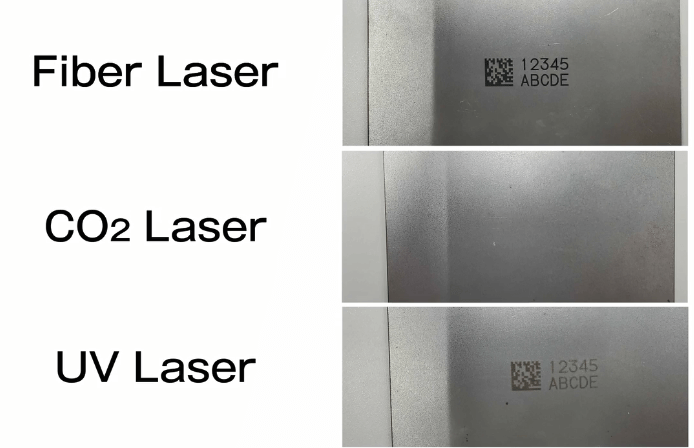

Metal-Iron

Fiber laser: The surface of the iron shows clear and contrasting markings.

CO2 laser: The metal barely absorbs the CO2 laser beam, so there is no visible marking on the material's surface.

UV laser: A low-contrast mark is created.

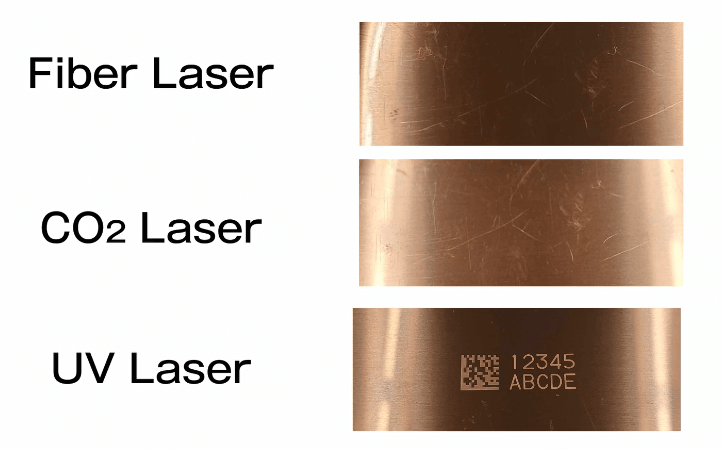

Metal-Brass

Aluminum brass is a highly reflective metal and we usually add oxygen to fiber laser cut brass. If a fiber laser is used to mark brass with only nitrogen, there will be no marking marks.

CO2 laser: The metal hardly absorbs the CO2 laser beam, so there is no visible marking on the material's surface.

UV laser: copper absorbs the UV laser quickly, making it very easy to achieve high contrast marks

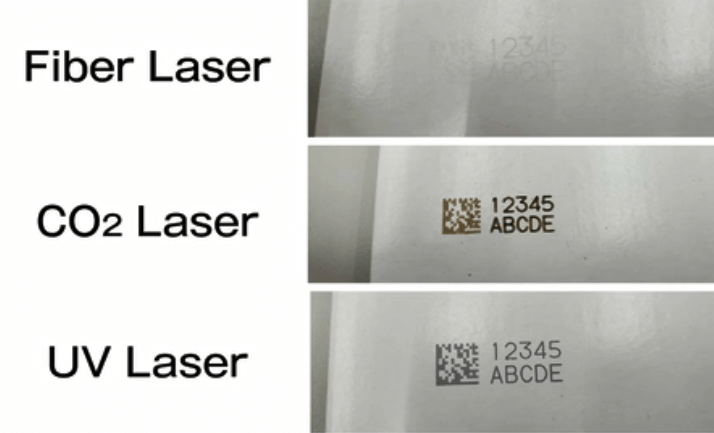

Non-metallic - white cardboard

We can clearly see that the CO2 laser provides the clearest marking marks for non-metallic materials. However, it is important to note that the CO2 laser marking machine needs to be set to a low power setting with air assist when marking flammable non-metals such as wood, cardboard and fabric. This will prevent the non-metal from burning.

Non-metallic - acrylic

For these transparent non-metallic materials, such as glass, transparent plastic or acrylic, the CO2 laser provides the best marking results. If you want the UV laser marking machine to achieve the same results when marking acrylic, you need to apply a colored pigment to the acrylic's surface or artwork tape.

In short, a fiber laser marking machine is the best choice for metal marking and a CO2 laser marking machine is the best for non-metal materials. If you want to be able to mark both metal and non-metal materials and do not need a very clear contrast, you can choose a UV laser marking machine.

Which laser type is suitable for me?

The fundamental difference between Fiber VS CO2 VS UV is that the material suitable for marking differs, so you can choose depending on the material your company needs to mark. If marking non-metallic materials such as wood, cardboard, plastic, etc., you can choose between CO2 and UV. So which of the two will suit you better? Can analyze the following points:

Marking requirements: If you have high marking depth, contrast and accuracy requirements, you can choose the CO2 laser.

Budget: You can choose a UV laser marker if you have a small budget.

Marking speed: The marking speed of the CO2 laser and UV laser is similar, but the overall UV laser is a little faster.

Conclusion

These are the basics of fiber, co2 and UV laser marking machines, which will help you choose a machine. If you want to buy a laser marking machine, you can contact our online customer engineers, who will give you the best solution.