A Guide to Buy Your First Fiber Laser Cutting Machine

With the increasing number of types and brands of fiber laser cutting machines, the quality and price of the machines vary.

Buying a fiber laser cutter for the first time can be difficult.

And as you get to know the machine better, you may find it even more difficult to choose. Initially, you only know that the higher the laser power, the deeper the thickness of the material to be cut. As you get to know the machine better, you learn that there are many brands of lasers, and then you need to research which laser brand is better.

You've probably learned that almost all laser brands have their strengths and weaknesses.

At this point, it will tear you up as to which machine to buy.

Fiber laser cutting is expensive and the wrong choice can cost your business money.

Here we will provide some basic information on fiber laser cutters and explore what to choose for your first purchase.

What is a fiber laser cutting machine?

A fiber laser cutting machine is a cutting machine that uses a fiber laser. A Fibre laser's unique operating principle allows it to reflect a higher-energy laser beam. Compared to other types of lasers, fiber lasers have a leading edge when it comes to metal cutting.

The laser wavelength of the fiber laser cutting machine is 1064 nm. The laser has a long life cycle and lasts approximately 15-20 years or more. It is suitable for metal marking by engraving, annealing and marking thermoplastics.

It is versatile and popular in many high-precision industries for processing and precision cutting.

The classification of fiber laser cutting can be based on several factors:

- Laser Power: Fiber lasers are available in a range of power levels, typically measured in watts (W) or kilowatts (kW). The power level determines the cutting capabilities of the laser, including the thickness and type of material it can cut efficiently.

- Cutting Bed Size: The size of the cutting bed can vary across different fiber laser cutting machines. The bed size determines the maximum size of material you can cut. However, many machines now come with a machine bottom feed function, so you don't have to worry about the length of the material you are cutting. Larger cutting beds are suitable for handling larger sheets or workpieces.

- Cutting Method: Fiber laser cutting can be classified based on the cutting method employed. Two common methods are:

a. Fusion Cutting: This method uses a focused laser beam to melt the material, creating a narrow cut. The commonly used auxiliary gases are oxygen and nitrogen. Air assisted during the cutting process blows away the gases generated during the cutting process in time and gives a neater cutting surface.

b. Flame Cutting: In this method, the laser beam heats the material to its ignition point, and a jet of oxygen is used to blow away the molten material, creating a cut. Flame cutting is typically used for thicker materials, such as metals. - Material Type: Fiber laser cutting can be classified based on the type of materials it can effectively cut. Common materials include:

Metals: Fiber lasers are particularly well-suited for cutting various metals, such as steel, stainless steel, aluminum, copper, and brass. - Automation Level: The fiber laser cutting machine is highly automated. Higher levels of automation may include features like automatic material feeding, part unloading, and integrated robotic systems for continuous cutting processes.

These classification factors can help identify the appropriate fiber laser cutting machine for specific applications and production requirements.

Fiber laser cutting machine working principle

All types of laser cutting machines work on a similar principle. The main process is that a high-energy laser beam is applied to the material and the material in contact with the laser beam sublimates instantly. This completes the cut. In simple terms, fiber laser cutting of metal is the process of sublimation of the metal in contact with the laser.

The size of the cut gap, the accuracy and the smoothness of the surface are related to the cutting accuracy and the laser's spot size.

6 important components of fiber laser cutting machine

The fiber optic cutting machine has six main components. The next introduces the well-known brands of each part and their role in the machine.

Laser source

The laser source is the core component of the CNC fiber laser cutting machine. Its role is to provide the laser beam to the laser cutter, where the laser beam is formed. The stability of the machine's output rate, the quality of the beam, the wavelength, etc., are laser related. If you are on a budget, I suggest you spend most of your budget on laser source.

Top 6 laser source brands

- IPG: The IPGp laser source is the best in terms of stability, engraving accuracy and service life and is ideal for laser cutting machines above 6000w. Its disadvantage is its high price.

- Raycus: The Raycus laser source has medium performance and its biggest advantage is its low price.

- Max: suitable for small ranges from 20 to 80 kHz, its performance is similar to that of the Raycus. And the most significant advantage is it's inexpensive. If it is difficult to choose between the Raycus and the Max, I recommend the Raycus.

- Trumpf: suitable for low power cutters up to 1500 watts, its overall performance is very good and inexpensive.

- Nlight: all performance and price are still good, for small businesses and low power machines is a good choice.

- Reci: particularly suitable for low and medium power machines up to 4000w and cheap.

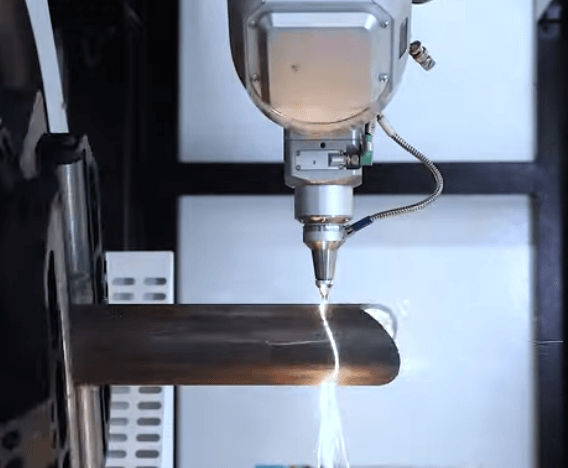

Laser head

The laser head is the final component in the beam propagation process and contains the focusing mirror, reflector and nozzle. Scattered laser photons are emitted from the laser and then converged by the reflector into a smaller diameter beam.

A curved mirror focuses on this to form the final laser beam. The distance from the focusing optics to the focus of the beam is equal to the focal distance, which is generally the optimum cutting distance.

Water chiller

The main function of the water chiller is to cool the working laser tube, prevent the optical components from breaking due to high operating temperatures, and ensure a constant output of a stable laser beam.

Water chiller technology has become very mature. And generally, well-known cutting machine manufacturers have already checked the quality of the water chiller for you. So you don't need to pay much attention to the water chiller when choosing a fiber laser cutting machine.

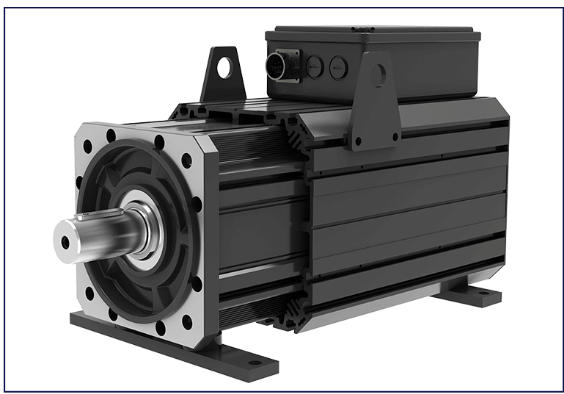

Servo Motors

Servo motors are a very important component of the fiber laser cutter and determine the machine's stability. Servo motors are the link between the machine and the control system and communicate commands from the control system to the machine so that the machine can cut according to the drawing.

A high-quality servo motor allows for more accurate cutting and thicker cuts.

Top 5 servo motors brands

Moog: higher price, well-known brand

Yaskawa: stable and reliable, high load capacity

Hiwin: Professional manufacturer of cutting machine parts

Harmonic Drive: all functions are moderate

Inovance: cheap and stable

Control system

The laser cutting machine's control system controls the laser head's stable and reliable operation.

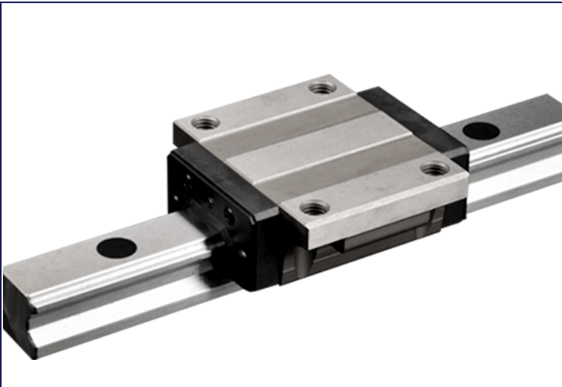

Rail & Rack

Rail in the X-, Y- and Z-axes. The high quality of the rails ensures transmission accuracy. The racks and rails have a dust protection device to ensure their long and reliable operation.

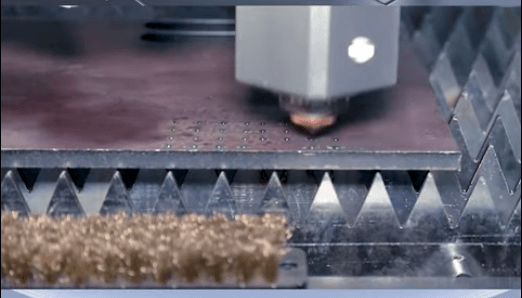

Work bed

The size of the bed of a fiber laser cutting machine determines the maximum size you can cut. Some machines are available with a bottom feed design so that the length of the material to be cut is not limited. There are three types of beds: cast, welded plate and welded tube, with one-piece cast iron beds being expensive and plate welded beds being cheaper.

Larger beds reduce loading and unloading times and workloads, which are also an important part of the fiber laser cutting machine.

Types of Fiber Laser Cutting Machines

Fiber laser cutting machines come in various types and configurations, each designed for specific applications and cutting requirements. Here are some common types of fiber laser cutting machines:

- Flatbed Laser Cutting Machine: This is one of the most common fiber laser cutting machines used to cut sheet metal. Place the metal to be cut on a fixed cutting bed and the laser beam will cut according to the pattern specified in the control system. It is versatile and can easily cut various materials and thicknesses.

- Flying Optics Laser Cutting Machine: In this type of machine, the laser beam remains stationary, while the cutting head and cutting bed move in a coordinated manner. The material is fed continuously, and the cutting head follows the programmed cutting path. Flying optics machines are known for their high cutting speeds and are suitable for large-scale production.

- Hybrid Laser Cutting Machine: Hybrid combines fiber laser technology with other cutting methods such as plasma or waterjet. This allows for enhanced cutting capabilities like thicker materials or complex shapes. Hybrid machines are versatile but may have higher initial costs.

- 3D Laser Cutting Machine: These machines are specifically designed for cutting three-dimensional objects and complex shapes. They employ robotic arms or articulated gantry systems to move the cutting head in multiple axes, enabling the laser to cut intricate designs on curved or irregular surfaces.

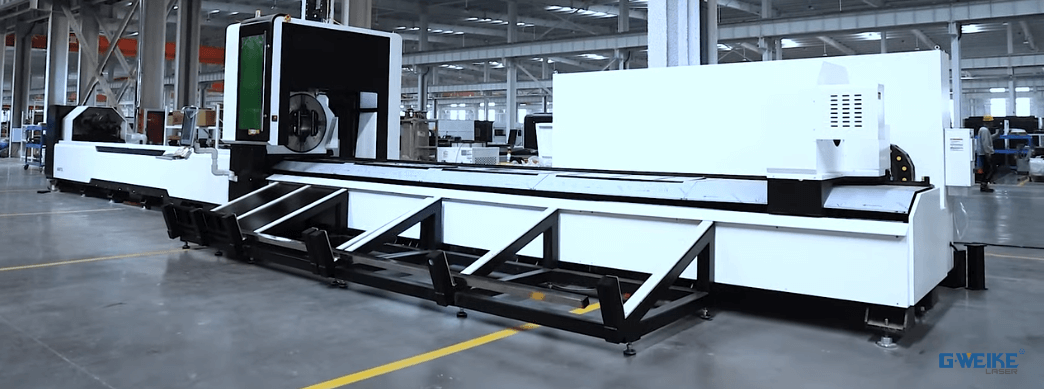

- Tube Laser Cutting Machine: Tube laser cutting machines are specialized for cutting cylindrical or tube-shaped materials, such as pipes, tubes, and profiles. They often feature a chuck or clamping system to secure the tube during the cutting process. Tube laser cutting machines can handle various tube diameters and wall thicknesses.

- Robotic Laser Cutting System: These systems integrate fiber laser technology with industrial robots, allowing for flexible and automated cutting processes. The robot arm carries the cutting head, enabling precise and versatile cutting on different shapes and materials. Robotic laser cutting systems are commonly used for complex or customized cutting applications.

These are just a few examples of fiber laser cutting machine types. Each type has its own advantages and is suitable for specific applications, so it's important to choose the right machine based on the material, thickness, shape, and production requirements.

Types of metals cut by the Fiber laser

The Fiber laser can cut almost all types of metal, including copper, aluminum, stainless steel, metal alloys, titanium, structural steel, carbon steel and many more. Here is a brief list of some of the metals we commonly use:

- Stainless steel: This is the most commonly used type of metal and can be cut using nitrogen so that the sheet's surface is not oxidation and burr-free. If you want to enhance the laser's perforation effect, you can apply a layer of oil to the surface of stainless steel.

- Aluminum: Both aluminum and copper are highly reflective metals, and the higher the purity of the aluminum, the more difficult it is to cut. Cutting with oxygen will oxidize the surface and make it rough.

- Titanium: Titanium is extremely corrosion-resistant and easily cut using a fiber laser cutting machine.

- Copper: Cutting copper requires an auxiliary gas to complete the cut.

Applications of Fiber Laser Cutting Machines

Different lasers have advantages and limitations and applications in different industries. Fiber laser is suitable for sheet metal processing, cutting, precision machining, etc. Some of the common applications of fiber laser cutting machines include.

Metal fabrication

Fibre laser cutting machines are used in the metal fabrication industry to cut a wide range of metals, including steel, stainless steel, aluminum, copper and brass, with high accuracy and speed. Fibre lasers can cut intricate shapes, holes, grooves and complex designs in sheet metal, plate and tube. They are ideal for producing components and parts used in the automotive, aerospace, machinery and electronics industries.

They cut sheet metal with a smooth cutting surface and a small heat affected area.

Automotive Industry

Fiber laser cutting machines play a crucial role in the automotive industry. They can cut various components, including chassis parts, body panels, brackets, exhaust systems, and intricate automotive parts. Fiber laser cutting machines enable the precise cutting of different metals in automotive manufacturing, ensuring high quality and accuracy in the final products.

Medical Equipment Manufacturing

The fibre laser cutting machine allows precise cutting of surgical instruments, implants and a variety of other medical devices. And the cutting process is so clean that no post-processing is required, ensuring the sterility and quality of medical components.

Electronic and electrical industry

In the production of electronic and electrical components, fiber lasers can cut thin metal sheets for circuit boards, control panels, electrical housings, connectors and more. Fiber lasers' precise cutting capabilities help achieve the tolerances and precision required for electronic and electrical applications.

Furniture and Interior Design

Fibre laser cutting machines use extensively in the furniture and interior design industry, and interior design industries for creating custom designs, patterns, and decorative elements. They can cut various materials such as wood, acrylic, plastics, and laminates to produce intricate shapes, patterns, and personalized designs for furniture, decorative panels, signage, and architectural features.

Jewelry Manufacturing

Fiber laser cutting machines can cut intricate designs and patterns into precious metals such as gold, silver and platinum. They enable jewellery manufacturers to create highly detailed and bespoke pieces with precision and efficiency.

Fiber laser cutting machine buying guide

- Machine power: The fiber laser cutting machine's power determines the cut metal's maximum thickness. If you need to cut metal plates more than 20mm frequently, it is recommended to choose a machine of 4000W or more. Of course, you do not need to purposely choose a machine with ultra-high laser power because the higher the laser power, the more expensive it is.

- Cutting slit: The spot diameter of the laser beam influences the width of the cutting slit. This size difference is very subtle and difficult to observe through the naked eye.

- Cutting machine parts: Of all the parts, the laser and laser head are recommended to choose a well-known brand.

- After-sales service: You need to know how the machine will repair after use, the charges and the after-sales service of the brand you are buying.

- Budget: The budget for buying a machine narrows the range of selected machines. Try to buy a machine from a big brand within a reasonable budget.

Because fiber laser cutting machines are expensive, if purchased from a small business, the manufacturer may have gone out of business or changed business sectors after a few years. At that point, if the machine breaks down, then you are difficult to access after-sales service.

Features of the Fiber laser cutting machine

- Good cutting quality: compared to conventional metal cutting, the surface of the laser cutting is smoother. Fiber laser cutting has a small heat-affected area and the workpiece is not deformed.

- High efficiency: simple cuts can be made in just a few seconds and the machine is highly productive.

- Fast cutting speed: the fastest cutting speed of the 8000w laser is up to 180m/min, which is an extremely fast production speed.

- No loss: the fiber laser cutter does not touch the material's surface during cutting. This contactless cutting greatly reduces machine loss and extends the life of the laser head.

- Compatible with a wide range of materials: fiber lasers can cut aluminum, brass, titanium, stainless steel, alloys, iron and many other metals, making them very compatible with a wide range of materials.

- Cons: The expensive 3000w fiber laser cutter sells for over $15,000.

Conclusion

This is some basic information about the fiber laser cutting machine, which will help you choose how to buy the machine.