CO2 VS Fiber Laser - Which One Should You Buy

Fiber laser cutting machines and co2 laser cutting machines are the most popular cutting machine options available today.

Although fiber laser cutting machines appeared in the public eye almost 30 years later than CO2, it still does not affect its popularity.

Both have different advantages. When cutting wood, acrylic, and other non-metals, CO2 laser cutting machines are a little better. And for sheet metal, copper, alloy, and other metals, you still have to choose fiber laser cutting machines to cut the right one.

In this article, I will clearly describe the differences between the two laser technologies and the correct application of each laser technology.

- Fiber lasers and their applications

- CO (2) lasers and their applications

- Fiber laser cutting machine VS CO2 laser cutting machine

- Cost: Fiber laser cutting machine VS CO2 laser cutting machine

- Laser cutting machine recommendation

- Conclusion

Fiber lasers and their applications

To know more about fiber laser metal cutting machines, understanding a good laser is our first step. Fiber laser mainly uses optical fiber to transmit the laser beam, so there is almost no energy loss. At the same time, the advantages of the short wavelength laser produced by fiber laser in cutting metal are very obvious. Fiber lasers produce wavelengths in the range of 0.78-2.2 μm.0.78-2.2 μm.

Applications of Fiber Lasers

By comparing the applications of fiber and CO2 lasers, you can better understand their uses. The main applications of fiber lasers are as follows.

- Telecommunications: Fiber lasers make the transmission of information across space a reality.

- Cable: Fiber optic cables transmit power with virtually zero loss and at extremely fast, interference-free speeds

- Medical: Using instantaneous energy generation of fiber lasers, we strive to instantly disintegrate cancer cells using lasers without damaging normal cells.

- Others: Fiber lasers are used in many common laser machines, such as laser welders and cleaners.

CO2 lasers and their applications

CO2 lasers have a much longer history compared to fiber lasers. Inside every CO2 laser cutting machine, we see a glass tube. Positive and negative electrodes are attached to both sides of the glass tube, and then an electric current acts with a gas mixture inside the tube to excite the gas atoms to produce a laser. It usually produces longer wavelengths, such as 9.3 µm, 10.2 µm, and 10.6 µm. Metals reflect these wavelengths, so they are often used to cut non-metals.

CO2 laser tube display

Applications of CO2 lasers

Medical: Unlike fiber optics, the laser wavelength of CO2 is highly soluble in water, making it the primary choice for treating many human tissue-based diseases.

Difference: fiber laser cutting machine VS CO2 laser cutting machine

CO2 laser cutting machines are not completely unable to cut metal, but cutting metal reflecting laser will damage the laser. Essentially, both are machines used to cut materials, so let's talk about the differences between the two:

Wavelength

| Machine | Wavelength |

| CO2 | 9.3-10.6 μm |

| Fiber | 0.78-2.2μm |

The wavelength is the main factor that affects the difference between the two. It is also the direct reason that affects the difference between the two cutting objects.

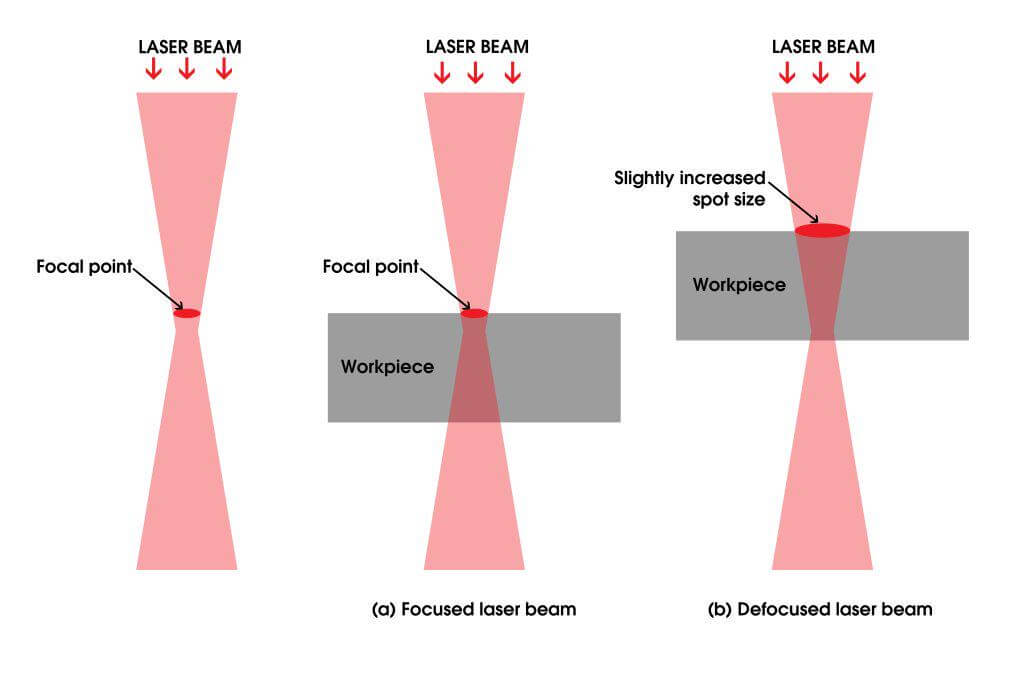

Spot size

The spot size affects the cutting width. The larger the spot size, the wider the cutting width.

Usually, the spot size of CO2 is much larger than that of fiber laser cutting machines. However, during the cutting process, we can change the size of the spot falling on the cutting material by adjusting the focal length of the machine.

Processing Materials

CO2 and fiber laser cutting machines are suitable for different material fields. Fiber laser cutting machines are suitable for cutting metals, while CO2 laser cutting machines are suitable for cutting non-metals.

However, CO2 can also cut metal with air assist and parameter setting, but it will damage the machine's laser head and laser tube. At the same time, it can not cut too thick metal. Otherwise, it will not cut.

But fiber can't cut non-metals because non-metals hardly absorb fiber lasers.

Compared with the two, CO2 can cut a wider range of materials.

| Material | fiber laser | CO2 laser |

|---|---|---|

| Carbon Steel | ✓ | ✓ |

| Stainless Steel | ✓ | ✓ |

| Aluminum | ✓ | ✓ |

| Copper | ✓ | |

| Brass | ✓ | |

| Iron | ✓ | |

| Silver | ✓ | |

| Acrylic | ✓ | |

| Wood | ✓ | |

| Leather | ✓ | |

| Glass | ✓ | |

| Marble | ✓ | ✓ |

Cutting thickness

Here I will not compare the cutting thickness of the two. Because the cutting thickness is related to the power of the machine, cutting speed, and other parameters and the cutting objects of fiber optic and CO2 is different, it is impossible to tell who can cut thicker products between the two.

The cutting machine will have a user manual with the recommended cutting parameters for various materials and the maximum cutting thickness. You can refer to the manual to determine how thick your machine can cut.

Processing speed

Under the same cutting conditions, the processing speed of the fiber laser cutting machine is a little faster. The general cutting speed of fiber optics is about three times faster than CO2.

And the greater the power the machine can achieve, the greater the processing speed will be correspondingly greater. For example, 500 watt fiber laser cutting machines and 300w fiber laser cutting machine processing speeds are completely different.

However, the processing speed of the cutting machine needs to be reduced as the thickness of the cut material increases. If the thickness of the cutting material reaches a specific value, the cutting speed of fiber and CO2 cutting machines will be almost the same.

Engraving Capability

CO2 laser engraving machines are suitable for engraving acrylic, wood, marble, leather, glass, and other non-metallic materials.

Fiber laser cutting machines are suitable for engraving various metal materials.

If you want to engrave or cut thicker plates, you have to choose a 500 watt fiber laser cutting machine or an even higher wattage machine.

Safety

Both are relatively safe compared to CO2 lasers. Generally, high power fiber laser metal cutting machines come with CE safety enclosures. The fully enclosed housing ensures that there will not be any laser leakage.

Both machines must be operated strictly with the safety manual, wearing goggles, safety clothing, and other requirements.

Cost: Fiber laser cutting machine VS co2 laser cutting machine

Machine Costs

The price of a fiber laser cutting machine is about 3-4 times more than a CO2 laser cutting machine for the same power.

High-end fiber laser cutting machines cost over $50,000, while high-end CO2 cutting machines cost over $20,000.

Operating Costs

The post-use cost of fiber optics is much lower than that of CO2 laser. The lifetime of a fiber optic machine is about three times longer than a CO2 machine, and it does not cost much extra money after use.

The gas will constantly lose in the laser tube during use, and when used for 1-2 years, it may need to be replaced with a new laser tube. Also, if you cut flammable materials or metals, you need to turn on the air assist, so the operating cost of the CO2 machine will increase again.

Maintenance Costs

CO2 machines operate mainly by integrating the laser beam through the laser tube and then reflecting the laser to the laser head using parts such as reflectors and focusing mirrors. So if your machine needs to work continuously, then it is recommended that you clean and maintain the beam path, radiating mirror, focusing mirror, and other parts every week.

Fiber laser cutting machine is simple routine maintenance, and the chances of laser failure are also very small. But if a single fiber fails, you must replace the entire laser module.

Electricity

Fiber laser cutting machines are about 3-4 times more efficient than CO2, so the power required for the same power fiber laser is much less than CO2.

Laser cutting machine recommendation

LF3015GA - Fiber laser cutting machine

Pros

- CE standard laser protection glass, fully enclosed machine

- Auto-focus 10 times faster than manual focus

- Equipped with industrial water coolers and with water cooling heat sinks to improve the service life of laser head

- Adopt automatic up and down exchange platform, save labor.

| Laser power | 1000W 2000W 3000W 4000W 6000W(Optional) | ||

|---|---|---|---|

| Dimensions | 8150*2825*2125mm | 10750*3350*2310mm | 15000*4018*2755mm |

| Working area | 3000mm*1500mm | 4000mm*2000mm | 6000mm*2500mm |

| Repeat positioning accuracy | ±0.02mm | ||

| Maximum speed | 120m/min | ||

| Max. acceleration | 1.5G | ||

| Voltage and frequency | 380V 50Hz/60Hz | ||

LC1390N - CO2 Laser Cutting Machine

Pros

- Four-sided feeding for maximum size cutting and engraving of materials

- Automatic lifting of the working table

- Automatic focus

- Hiwin guide rail for high positioning accuracy

| Laser - Type | Sealed CO2 laser tube |

|---|---|

| Laser power | 80W 100W 130W 150W 200W (optional) |

| Cutting Area | 1300mm x 900mm |

| Whole Machine Size | 1820* 1310* 1070mm |

| Cutting Speed | 0 - 24,000mm/min |

| Resetting Positioning Accuracy | ±0.05mm |

| Working Voltage | AC 110 -220V±10%, 50-60Hz |

| Gross Power | <1,500W |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Minimum Shaping Character | English 1x1mm |

| Work Table | 18cm lift platform |

| Driving System | stepper |

| Cooling Mode | water-cooling and protection system |

| Auxiliary Equipments | Exhaust-fans, air-exhaust pipe |

| Controlling Software | DSP control system |

| Compatible Software | CorelDraw AutoCAD Photoshop |

Conclusion

If you're buying a machine, there's no need to get hung up. If your cutting material is more metal, go with a fiber laser. If your company cuts more non-metallic materials, use a CO2 laser.

This article is just a comparison of the differences between the two machines. If you want to buy either type of machine, you can contact our staff directly. We are a China laser cutting machine manufacturer with 20 years of manufacturing experience as of 2023.