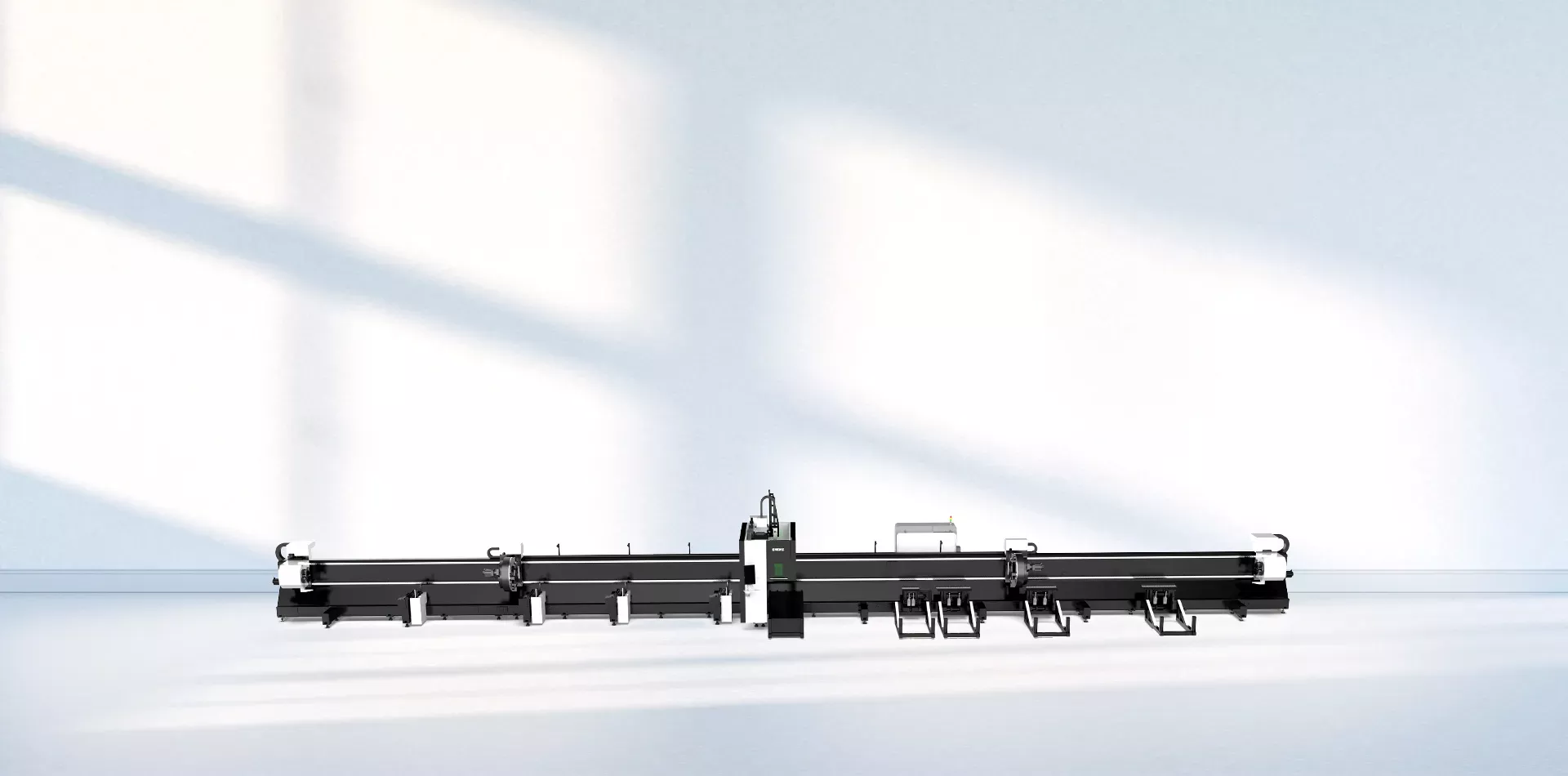

T4 SERIES

Four-chuck Heavy-duty Fiber Laser Tube Cutting Machine

Video Show

It ensures unloading for the last round or loading for the next round, while carrying out pipe cutting. Seamless collaboration, remarkable efficiency.

Flexible & Diverse combinations for automatic switch between 3+1, 2+2, and 1+3 modes to adapt to various working conditions, solving the problems of bending and deformation in extra-long heavy pipe processing.

500 heavy-duty pneumatic chucks, process round tubes with a diameter of 50 - 500mm and square tubes with a side length of 50x50 - 350x350mm. The Four-chuck flexible system achieves true tailing-free cutting.

Supports up to 2000kg single heavy tube and 12m long tube loading, cutting, unloading.

Auto rollers realize intelligent support and centering, prevent tube from hanging and swing, and further secure cutting accuracy.

Lowers the center of gravity of pipes to facilitate a more stable cutting process, a smoother loading and unloading process.

| Machine model | 12050T4 |

|---|---|

| Laser power | 6000W-20000W |

| Clamping range | Round tube (φ50-φ500mm) Square tube (□50X50-□350X350mm) |

| Max. rotation rate | 30r/min (decreases with increased weight of the pipes) |

| Effective cutting length | 12500mm |

| Single pipe load-bearing | 2000KG |

| Chuck structure | 500 Pneumatic Chuck |