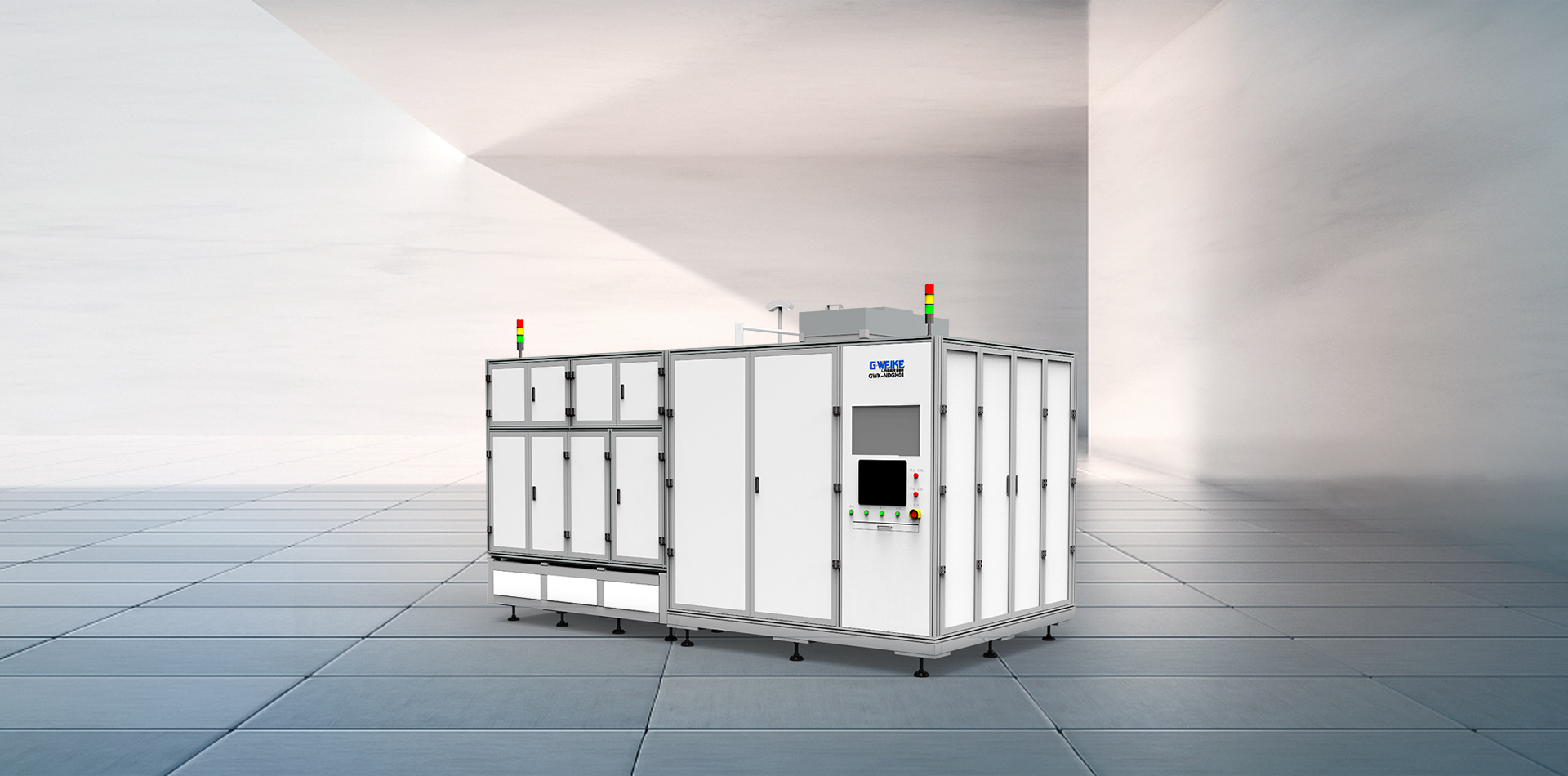

New energy series

Top Cover Laser Welding Machine

Video Show ![Video Show]()

Capable of barcode scanning for power battery cells,

fully automatic loading and unloading, automatic door

battery fixture clamping and baseline positioning, automatic

upper and lower protective cover cycling, fully automatic welding,

while blowing high-purity nitrogen to improve welding quality,

automatic sorting of OK/NG products, and welding information

parameters traceable by MES.

Using a turbine-type dust suction disc, efficiently removing welding fumes, automatic post-welding detection, automatic edge rolling and cleaning, effectively ensuring the working environment and reducing workpiece wear, extending service life.

Utilizing a marble base, linear motor drive,

high positioning accuracy, and stable welding

performance. Compact structure, fully utilizing

laser performance, significantly improving

production efficiency.

Sealing welding of top covers in the production line of square aluminum shell batteries for new energy lithium batteries

| Machine model | GWK-NDGH01 |

|---|---|

| Power Supply | 380V/50HZ |

| Rated power | 120KW |

| Welding repeatability | ≤±0.01mm |

| Machine weight | 5.5T |

| Overall dimensions | L5100*W3000*H2600(mm) |

| Weld penetration depth | 0.5mm≤h≤1.1mm |

| Weld bead width | 0.8mm≤w≤1.2mm |

| Pressure (proof) test | ≥1.0Mpa |

| Flanging | ≤0.1mm |

| Welding speed | 80mm/s~200mm/s |

| Yield rate | ≥99.9% |

| Uptime | ≥98% |

| Welding throughput / Efficiency | ≥15PPM |