New energy series

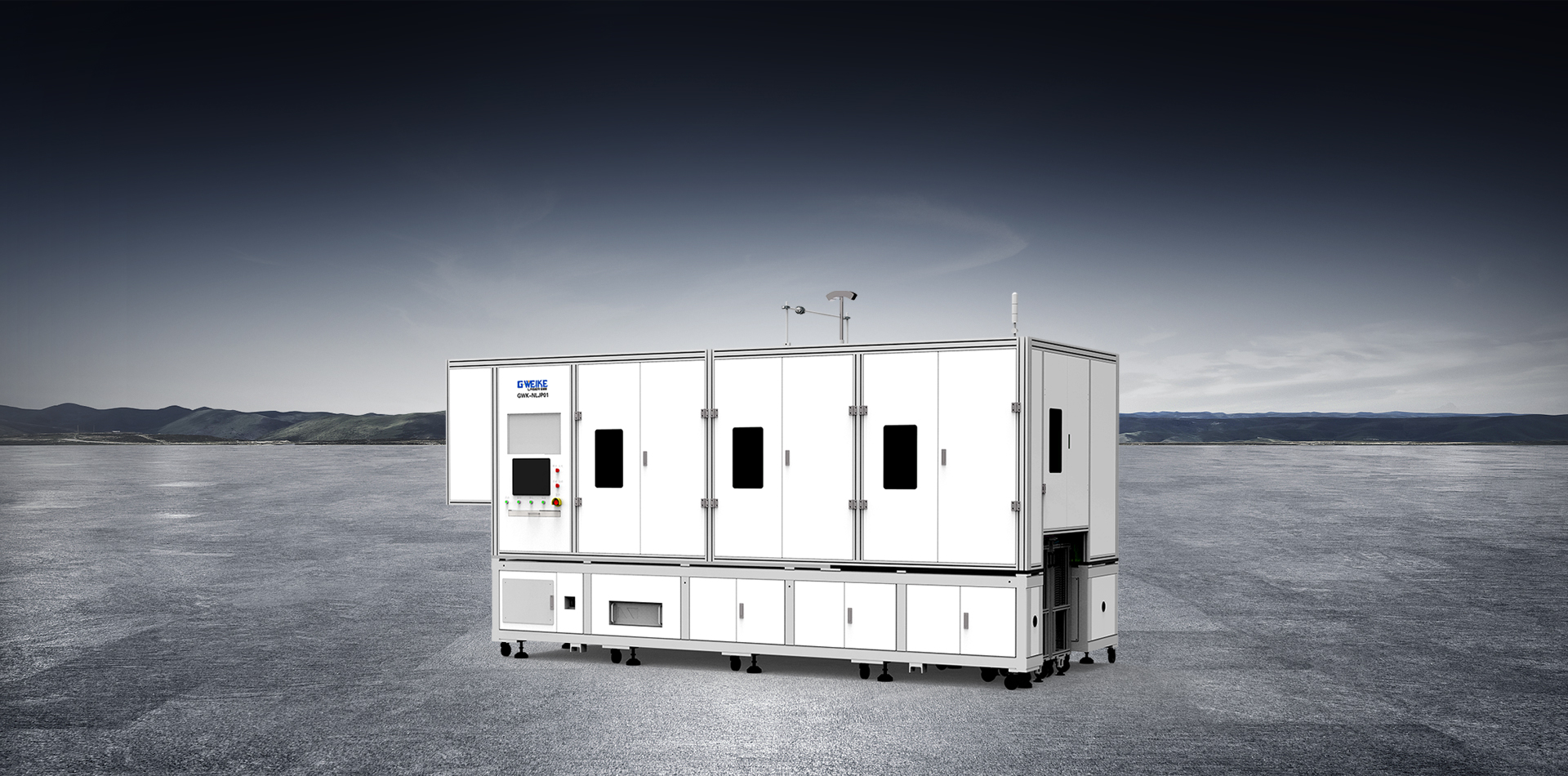

Soft Connection Laser Welding Machine

Video Show ![Video Show]()

Through automatic loading of battery cores, automatic loading of cover sheets, secondary loading of cover sheets, secondary loading of battery cores, etc., achieving automatic completion of loading and unloading, fully automatic intelligence throughout the process, efficient collaboration.

Efficiency reaching 15PPM, high positioning accuracy, and stable welding performance; reasonable layout, fully utilizing laser performance, greatly improving production efficiency.

Welding of soft connections between cover sheets and battery cell packs in the production line of square aluminum shell batteries for new energy lithium batteries

| Machine model | GWK-NRLJ01 |

|---|---|

| Power supply | 380V/50HZ |

| Rated power | 100KW |

| Welding repeatability | ≤±0.01mm |

| Machine weight | 5T |

| Overall dimensions | L5100*W2000*H2800(mm) |

| Weld penetration depth | 0.5mm≤h≤1.2mm |

| Weld bead width | 0.8mm≤w≤1.2mm |

| Battery cell damage rate | =0% |

| Welding speed | 80mm/s~100mm/s |

| Yield rate | ≥99.8% |

| Uptime | ≥98% |

| Welding throughput / Efficiency | ≥15PPM |

| Overall Dimensions | L8250*W1850*H2400(mm) |