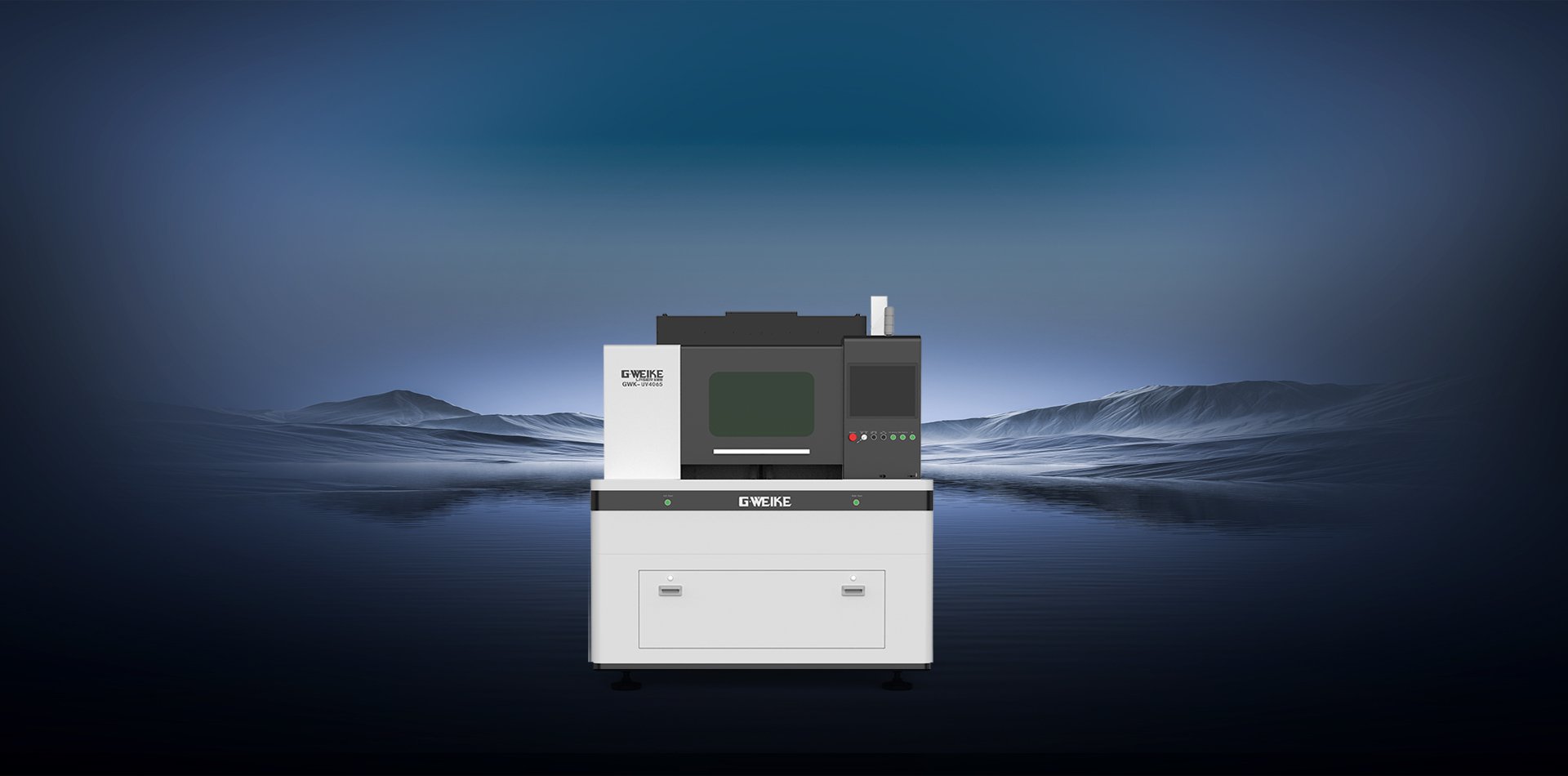

Ultrafast Series

Dual-Platform Precision Laser Cutting Machine

Video Show ![Video Show]()

Utilizing ultraviolet picosecond laser, cold processing without carbonization phenomenon; linear motor platform assembled on a marble base, high precision, low maintenance cost.

High-precision mirror processing, high accuracy,

no burrs in cutting; non-contact processing,

no stress deformation, high product qualification rate.

Dual-table design with independent operating platforms, saving loading and unloading time, faster and more efficient processing.

FPC shapes, rigid-flex board opening, PCB separation, camera module, fingerprint recognition module cutting

| Machine model | GWK-UV4065 |

|---|---|

| Laser Wavelength | 355 nm / 532 nm (optional) |

| Laser Power (options) | 15 / 20 / 30 W (optional) |

| Cutting Range | 400 × 650 mm (dual table) |

| Machining Thickness | ≤ 2 mm |

| Beam Quality | ≤1.3 |

| Laser Safety | Class IV |

| Max Scan Speed (Galvo) | 6000 mm/s |

| Repeatability | ±0.002 mm |

| Comprehensive Accuracy | ±0.03 mm (≤300 mm) |

| Cooling | Water‑cooling |

| Ambient Temperature / Humidity | 22 ± 2 ℃ / 30–60% |

| Power Requirement | AC 220 V / 22.5 A, 5 kW |

| Machine Size (W×D×H) | 1650 × 1800 × 1950 mm |