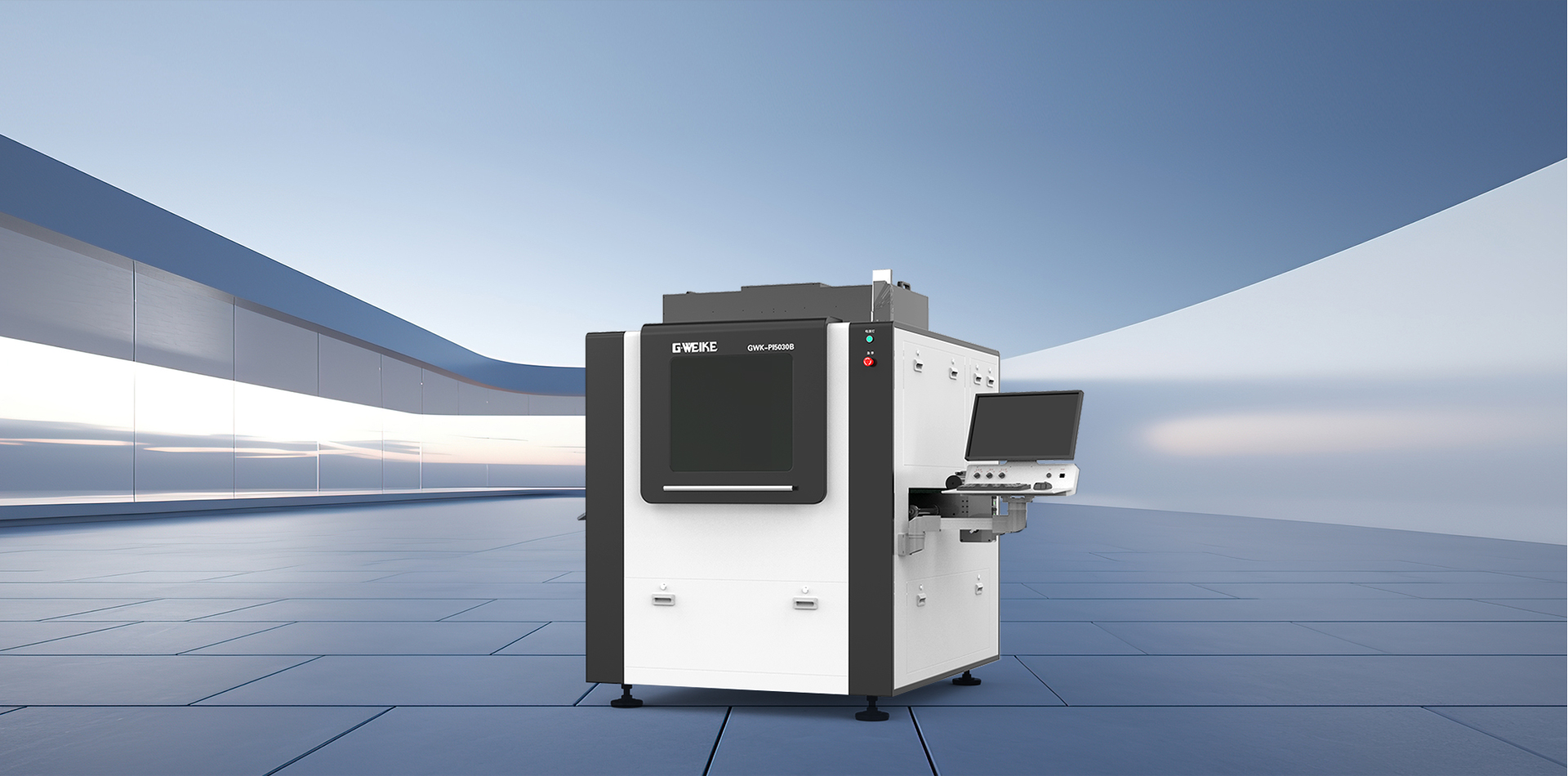

Ultrafast Series

Dual-Head Roll-to-Sheet PI Film Cutter

Video Show ![Video Show]()

Using picosecond laser,

fine beam spot, precise cutting seam,

high cutting accuracy.

Dual-mirror dual-head synchronous processing,

high cutting efficiency; using platform and mirror linkage

to avoid accuracy errors caused by splicing.

Automatic feeding, automatic cutting, automatic receiving, roll-to-sheet processing, automated execution of processing programs for unmanned operation, low labor costs.

FPC cover film, PI film, electromagnetic film cutting

| Machine model | DC0605 |

|---|---|

| Laser Type | CO₂ Seal-Off (Sealed) — C55 (optional) |

| Laser Safety | Class IV |

| Cutting Range | 500 × 600 mm |

| Machining Thickness | ≤ 1 mm (films) |

| Max Machining Speed | 300 mm/s |

| Repeatability | ±0.01 mm |

| Comprehensive Accuracy | ±0.05 mm |

| Cooling | Water-cooling |

| Ambient Temperature / Humidity | 22 ± 2 ℃ / 30–60% |

| Power Requirement | AC 220 V / 14.5 A, 3 kW |

| Machine Size (W × D × H) | 1350 × 1300 × 1600 mm |

| Kerf Width (typical) | 80–150 µm (by material)/td> |

| Edge Appearance | No visible burrs at 10×, minimal HAZ |