This guide compares fiber vs CO₂ laser cutting from an industrial, production-floor perspective. We focus on metals vs non-metals, speed and edge quality, typical tolerances and heat-affected zone (HAZ), and total cost per part. You’ll also find selection tips by use case and a quick matrix to decide faster.

Materials & Thickness (Metal / Non-metal boundary)

Why the boundary exists. Fiber lasers operate near ~1 µm wavelength; metals absorb this energy efficiently, enabling fast, stable cutting even on reflective alloys. CO₂ lasers operate near ~10.6 µm; non-metals (wood, acrylic/PMMA, paper, many polymers, leather) generally couple well to this wavelength, giving clean edges and polished acrylic finishes.

Metals (carbon steel, stainless, aluminum, copper/brass).

Default choice: Fiber. For most sheet-metal work, fiber is the baseline due to coupling efficiency, speed, and lower upkeep of the beam path.

Reflective metals: Copper and brass present higher reflection risk for CO₂ optics; fiber handles these materials more safely and productively when set up correctly.

Thickness bands (practical guidance):

- Thin sheet (< 8 mm): Fiber typically offers the highest productivity, especially with nitrogen for clean, weld-ready edges.

- Mid-thickness (8–20 mm): Both can be viable depending on steel grade, gas choice, and edge requirements. Fiber with appropriate parameters is increasingly dominant here.

- Heavy plate (> 20 mm): Choice is driven by edge quality target, piercing behavior, and whether oxygen-cut oxide is acceptable before downstream steps (welding, coating). High-power fiber can handle many heavy-plate cases; where ultra-smooth edges are critical and throughput is secondary, alternative processes or parameter strategies may be considered.

Non-metals (acrylic, wood, paperboard, many plastics, rubber-like materials, leather).

Default choice: CO₂. CO₂ delivers stable, attractive edges, especially the glossy/polished edge on acrylic that signage and display work often requires.

Edge finish matters. Where flame-polished acrylic edges or minimal charring on organic materials is desired, CO₂ remains the straightforward route.

Limits. Some plastics (e.g., chlorine-containing) are restricted for safety reasons. Always verify material compatibility and ventilation/filtration requirements.

Four Core Metrics: Cut Quality, Speed, Tolerance, HAZ

1)Cut Quality (edge appearance & downstream readiness)

Fiber on metals

With nitrogen: Bright, oxide-free edges that are usually weld-ready and paint-ready with minimal prep.

With oxygen: Higher cutting speed and easier piercing on some thicknesses, but an oxide layer is formed; plan for cleaning/grinding before critical welds or coatings.

CO₂ on metals: Capable in some thickness ranges but generally slower and more sensitive to reflection on certain alloys. Edge appearance can be acceptable but is less consistent in modern throughput-focused lines.

CO₂ on non-metals

Acrylic:Signature polished, glossy edge with the right parameters—often a selling point in signage and display.

Wood/paperboard/leathers: Clean, controllable kerf with parameter tuning; some materials may show edge darkening inherent to thermal processing.

2)Speed (throughput)

Metals: Fiber typically excels—especially on thin and mid-thickness stainless and mild steel—thanks to energy coupling and beam characteristics. On heavy plate, speed is bounded more by piercing stability, gas choice, nozzle strategy, and part geometry. Non-metals: CO₂ is efficient and straightforward, particularly for acrylic and wood where a single pass can produce a finished edge.

3)Tolerance (typical)

Treat tolerance as a range rather than a fixed promise: it depends on machine rigidity, motion control, nozzle size and standoff, focus strategy, material lot, and path planning. In thin metal sheet with tuned parameters, sub-millimeter feature accuracy is typical; as thickness increases, kerf geometry and taper introduce variation. Extremely small holes and tight inside corners demand parameter recipes and may benefit from lead-ins, micro-joins, and adjusted acceleration limits. For acrylic and other non-metals, CO₂ can deliver precise edges; thermal behavior of the substrate (e.g., internal stresses in extruded vs cast acrylic) affects final dimensional stability.

4)HAZ (heat-affected zone)

Fiber on metals: Narrow HAZs are achievable with correct focus, power density and traverse speed. In stainless and aluminum, nitrogen cutting reduces post-processing. CO₂ on non-metals: HAZ manifests as darkening/charring for organics and as surface melting/polish for acrylic. For industrial parts that mate or seal, account for this in tolerances and finishing.

Operating Cost (Gas / Energy / Consumables)

Energy. Fiber systems generally deliver higher wall-plug efficiency for metal cutting. In day-to-day factory terms, this means more parts per kWh on thin-to-mid sheet. CO₂ systems draw differently, and their beam path (resonator to mirrors to lens) adds alignment and maintenance tasks that show up in both energy and upkeep time.

Assist gas strategy.

- Oxygen (O₂):Favours speed and easier piercing on steels. Leaves an oxide layer—fine for non-critical edges, but welding or coating steps may require extra cleaning.

- Nitrogen (N₂): Produces bright, oxide-free edges on stainless and mild steel; popular when you want weld-ready / paint-ready parts off the table. Expect higher gas consumption and plan the supply (cylinders, bulk tanks, or generators).

- Air (filtered, dry): Viable in some applications for cost control, with trade-offs in edge appearance.

- Non-metals: Often cut without high-pressure assist, but adequate fume extraction/filtration is essential.

Consumables & maintenance.

- Fiber: Short, sealed beam path reduces mirror cleaning/realignment. Nozzles, lenses, protective windows, and filters are routine consumables.

- CO₂:Additional mirrors and longer beam delivery mean more optics care and occasional alignment. Plan schedules and spares accordingly.

Total cost per part. Consider (energy + gas + optics/consumables + post-processing + changeover time) divided by shipped parts. Many teams discover that running N₂ on fiber eliminates downstream grinding or rework, which more than offsets gas spend.

Selection Tips (By industry, thickness, and edge-quality goals)

General job shops (mixed metal sheet, high variety): Choose fiber. Use N₂ for weld-ready stainless/mild steel, switch to O₂ when oxide is acceptable and you want higher speed on certain jobs. For copper/brass, fiber with proper parameters and process monitoring is the practical route.

Heavy steel fabricators (structural parts, brackets, frames): Start with fiber and tune piercing strategies and nozzles for stability. If you routinely accept an oxide edge (pre-weld grind anyway), O₂ cutting may unlock the best takt time. Where edge cosmetics dominate and budgets allow, N₂ yields the cleaner edge at higher gas cost.

Food/medical equipment (stainless, downstream hygiene, clean welds): Fiber + N₂ is the standard combination for bright edges and fewer post-processing steps before sanitary welds.

Acrylic signage & displays (polished edges are the "product"): CO₂. It produces the glossy edge clients expect. Keep in mind ventilation and filtration, especially for high-volume runs.

Electronics enclosures/precision panels (small holes, slot patterns): Fiber with refined hole strategies (reduced power at pierce, ramped frequency, micro-tabs). Expect to iterate “recipes” per alloy and thickness to get stable micro-features.

Mixed-material prototyping (wood fixtures + metal brackets): Consider two-platform workflow if volumes justify it: fiber for metal brackets; CO₂ for jigs, fixtures, and acrylic display elements.

Rule of thumb: Start from the desired edge (weld-ready? visible cosmetic edge? paint-ready?) and gas economics, then finalize laser type and power.

Fiber vs CO2 Matrix (Industrial quick reference)(H2)

| Parameter | Fiber Laser Cutting | CO₂ Laser Cutting |

|---|---|---|

| Best-fit materials | Metals (CS/SS/AL) incl. reflective alloys (Cu/Brass) with correct setup | Non-metals (acrylic/PMMA, wood, paperboard, leathers, many plastics) |

| Typical metal thickness focus | Thin → mid → many heavy-plate cases with high power | Select metal ranges; generally less favored for modern metal throughput |

| Speed on thin metal | Very high (especially with N₂) | Lower |

| Edge character (acrylic) | Not applicable | Polished, glossy edge is a strong advantage |

| Small holes / fine features | Strong with tuned recipes; watch kerf taper on thick plate | Strong on non-metals; on metals depends heavily on setup |

| HAZ (relative) | Narrow with tuned focus/speed; controllable | Organics: darkening risk; Acrylic: molten/polished edge by design |

| Assist gas (typical) | N₂ for clean edge; O₂ for speed; Air in specific cases | Often low-pressure or none on non-metals; O₂/N₂ used case-by-case on metals |

| Reflective metals | Well-suited (with protection & parameters) | Riskier for optics and stability |

| Maintenance | Lower beam-path alignment burden | More mirrors and beam alignment care |

| Running cost (metal) | Generally lower per part at volume | Generally higher per part for metals |

Rule of thumb: Choose power around your top five weekly materials/thicknesses. Often a swap table yields more output than oversizing power for a few thick jobs.

Power

- 3–6 kW: Bread-and-butter for thin/mid-sheet.

- 12 kW+: Thick plate and high-speed bright-edge stainless with N₂.

- Decide by target cycle time (takt), not a single “max thickness”.

Lenses

- Short FL: narrow kerf, fast on thin sheet.

- Long FL: stable thick-plate piercing, straighter edges.

- Works with nozzle orifice & standoff to shape kerf/gas flow.

Options

- Automation first: Swap table → biggest OEE boost; load/unload helps high-mix, mid-volume.

- Plate & tube: Makes sense when tubes are ≥20–30% long-term.

- Spares & upkeep:Protective windows, nozzles, filter media in rotation.

Recommended Models

Metals • Fiber

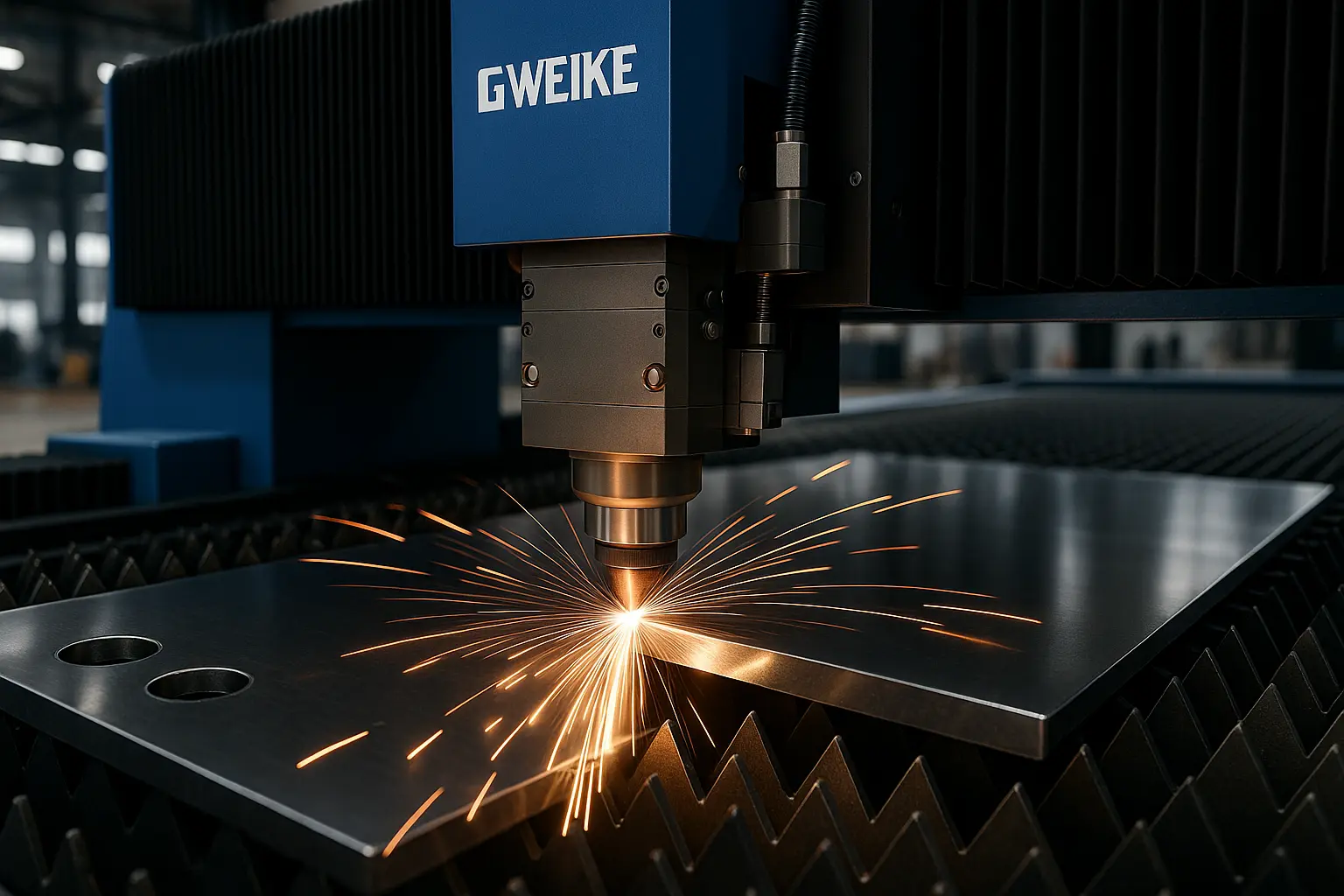

GH / GA Series — Fiber (Metals)

Built for production metalwork with fast acceleration, stable motion, and support for nitrogen clean-cut recipes. Typical use: cabinets, frames, enclosures, panels, and precision brackets in carbon steel, stainless, and aluminum.

Non-metals • CO₂

E PRO Series — CO2 (Non-metals)

Purpose-built for acrylic, wood and other non-metals with crisp kerfs and the polished acrylic edge designers expect. Ideal for signage, displays, packaging prototypes, and fixtures.

Safety & Ventilation (brief)

Always provide adequate ventilation or certified filtration matching the materials you process. Avoid restricted materials (e.g., chlorine-containing plastics). Keep appropriate fire suppression within reach, follow PPE requirements, and manage fume extraction carefully—especially for metals and any process that produces fine particulates.

Conclusion

If your workload is primarily metal, a fiber laser is the modern default—especially when you want weld-ready, paint-ready edges at industrial takt times. If you deliver acrylic displays, signage, and organic substrates, CO₂ gives you the signature edge quality your clients see and feel. For mixed shops, many operations standardize on fiber for metals and use CO₂ (or subcontract) for acrylic/wood. The optimal setup balances edge requirements and total cost per part, not just machine price.

FAQ

Q1. Should I choose fiber or CO₂ for metal cutting?

A: Choose fiber in most cases. It couples efficiently into metals, handles reflective alloys with proper setup, and delivers higher throughput on thin-to-mid sheet. CO₂ can cut metals but is less common today for volume work.

Q2. Can fiber cut copper or brass?

A: Yes. With appropriate parameters and protection, fiber is the safer and more practical choice for high-reflectivity metals.

Q3. Why does N₂ vs O₂ assist gas change the result so much?

A:O₂ promotes fast cutting and easier piercing but leaves an oxide layer. N₂ yields bright, oxide-free edges that are usually weld-ready, at higher gas consumption. Total cost per part depends on how much post-processing O₂ edges would require.

Q4. What about very thick steel?

A: High-power fiber can handle many heavy-plate jobs. Decide by required edge appearance, piercing stability, and gas economics. If oxide is acceptable and you grind before welding anyway, O₂ can maximize throughput; for cleaner edges off the table, N₂ is preferred.

Q5. We cut mainly acrylic and wood—do we need fiber?

A:No. CO₂ is the straightforward choice for these materials, and it delivers the polished acrylic edge valued in signage/displays.

Q6. What drives tolerance in real production?

A: Machine rigidity and motion control, nozzle size/standoff, focus strategy, gas dynamics, material batch, and the CAM path (lead-ins, micro-joins). Always validate a parameter “recipe” on your actual part geometry and alloy.

Get a Quote

Tell us: materials, max thickness, and edge quality target (weld-ready, polished acrylic, paint-ready). We’ll recommend the right platform (GH/GA for metal fiber; E PRO for non-metals), power, and gas strategy for your parts and takt time.