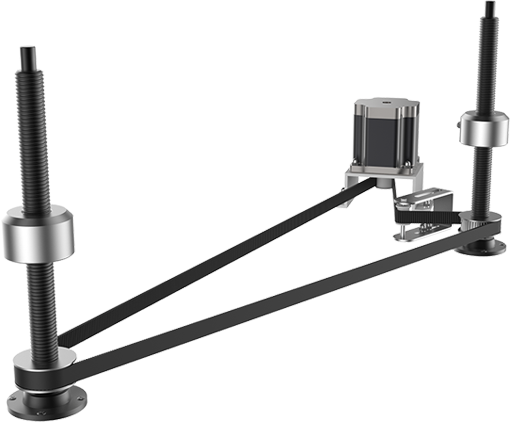

Up to ~180 mm motorized Z travel accommodates taller jigs and varied thicknesses.

Auto focusing makes the laser head focus easily and quickly. The CO2 laser cutting machine does not need to adjust the focal length by hand, saving much time and has higher accuracy.

Smooth, repeatable motion helps fine features stay sharp. Industrial-grade safety/limit components deliver reliable triggering and longer service life in daily production.

Stable beam quality and focused energy density enable glossy acrylic edges and crisp engravings with the right airflow and lens care.

Convenient - Engineers can remotely control computers and machines, adjust parameters and solve problems.

Efficiency - One PC can control several machines.

U.S. optics from American Photonics. Proven 14% beam transmission improvement vs. other optics. High strength gold-plated lenses and aspheric focusing lenses made by II-VI Company, USA.

High focus, high transmittance. The lenses can not only ensure the quality of the machine but also make the optical system run a long time with high efficiency and low cost.

Lower noise, low vibration, running more smoothly, higher torque, higher acceleration, higher precision, better acceleration performance.

The fan can be started by one button. You can control the fan independently.

Both knife blade and honeycomb platforms for cutting and engraving.

Environmentally friendly and pollution-free laser can be directly used indoors.

Filter large particles in bags.

HEPA filtration larger than 0.03UM particle.

Activated carbon adsorption system.

| Laser - Type | Sealed CO2 laser tube |

| Laser Power | 80w 130W 150W |

| Cutting Area | 1300*900mm |

| Whole Machine Size | 1800*1350*1050 |

| Cutting Speed | 0 - 24,000mm/min |

| Resetting Positioning Accuracy | ±0.02mm |

| Working Voltage | AC 110-220V±10%, 50-60Hz |

| Gross Power | <1,500W |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Minimum Shaping Character | English 1x1mm |

| Work Table | 18cm lift platform |

| Driving System | Stepper |

| Cooling Mode | Water-cooling and protection system |

| Auxiliary Equipments | Exhaust-fans, air-exhaust pipe |

| Controlling Software | DSP control system |

| Compatible Software | CorelDraw AutoCAD Photoshop |

Acrylic signage and lightboxes, wood crafts and latticework, MDF display fixtures, leather patches and personalized gifts, paper prototyping and small-batch packaging—across non-metal applications.

Advertisement industry special laser cutter for acrylic.

MORE

Adopeted dual laser heads, equal to two CO2 laser cutting machines, which greatly improvessing efficiency.

MORE

Be designed specially for non-metallic material, stable performance.

MORE