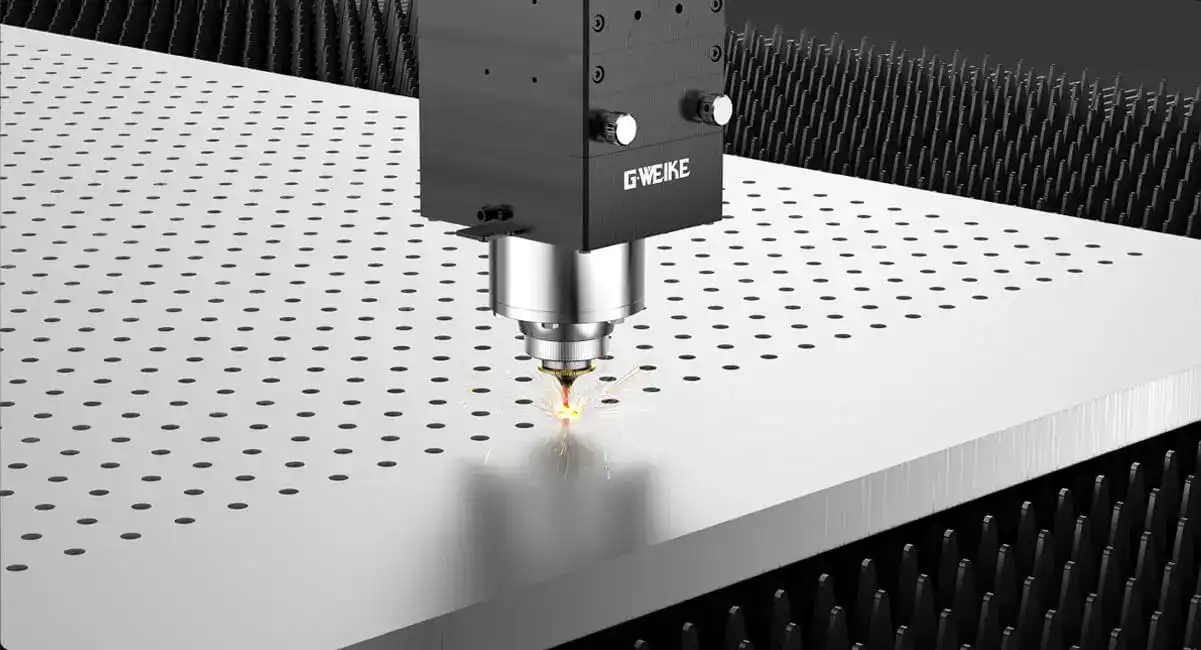

LC1325M — CO₂ Laser Cutting Machine for Multi-Material Processing

LC1325M is designed for workshops and factories handling both metal and non-metal materials on a large working area. With a stable motion system and auto-focus height control, it helps improve consistency and reduce setup time across mixed-material jobs.