1. Overview: Why Industrial Laser Cutting Dominates Modern Fabrication

Over the past decade, industrial laser cutting machines have become core equipment in global sheet metal manufacturing. From automotive components and electrical enclosures to elevator panels, machine frames, HVAC parts, and precision engineering, laser cutting has rapidly replaced plasma, flame cutting, and many mechanical processes because it offers:

- Higher precision and tighter tolerances

- Higher cutting speeds and shorter lead times

- Minimal thermal distortion and cleaner edges

- Full digital control and easy automation

- No tooling, no punching dies, fast product changes

An industrial laser cutting machine is not just a cutting device — it is a digital manufacturing platform that can integrate:

- CAD/CAM and nesting software

- MES/ERP systems

- Automated loading/unloading and storage towers

- Robotic sorting and bending cells

- Real-time process monitoring and data tracking

This guide explains what an industrial laser cutting machine is, how fiber laser cutting works, what types of systems exist, the metals and thicknesses they can process, and how to choose the right model — such as LF3015GA, LF4020GH, or LF3015LN — for your factory.

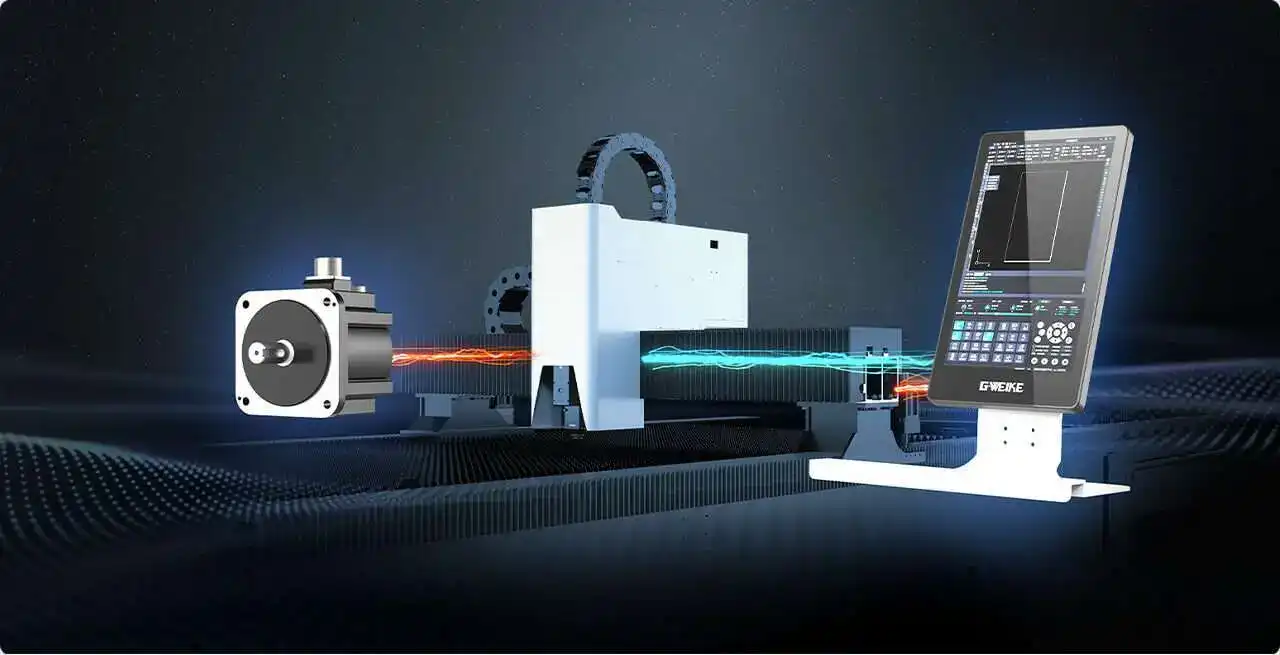

2. What Is an Industrial Laser Cutting Machine?

An industrial laser cutting machine is a high-precision CNC system that uses a powerful fiber laser source (typically 1–20 kW or higher) to cut metal sheets and plates with excellent speed and accuracy. Compared with consumer CO₂ or diode machines, industrial fiber laser cutters are designed for full-scale production and 24/7 operation.

Key characteristics of industrial systems include:

- Large-format cutting beds (e.g. 3015, 4020, 6020, 8025, 12025)

- Heavy-duty welded machine frames with stress relief

- Dual servo-driven gantries and precision guideways

- Automatic dual exchange tables for continuous cutting

- Support for ultra-high-power laser sources up to 20 kW+

- Integration with loading towers and robotic automation

The reason fiber lasers dominate metal cutting is their wavelength (around 1.064 μm), which is rapidly absorbed by metals. This allows very high cutting speeds, low running costs, and outstanding edge quality on carbon steel, stainless steel, aluminum, brass, and copper.

3. How Industrial Fiber Laser Cutting Works

Industrial fiber laser cutting can be understood as the interaction of four core subsystems:

3.1 Fiber Laser Source (1–20 kW)

The fiber laser source is the heart of the system. Manufacturers such as IPG, Raycus, Max, or nLIGHT provide sources ranging from:

- 1–3 kW — entry-level thin sheet metal fabrication

- 6–12 kW — mainstream industrial production

- 15–30 kW — heavy plate cutting and ultra-high-speed stainless steel

Higher power delivers:

- Higher cutting speeds

- Greater thickness capacity

- Faster piercing on thick plates

- Lower cost per part in high-volume production

Typical cutting capacity (approximate ranges):

| Laser Power | Carbon Steel | Stainless Steel | Aluminum |

|---|---|---|---|

| 3 kW | up to 12–16 mm | up to 6–8 mm | up to 4 mm |

| 6 kW | up to 20–25 mm | up to 10–12 mm | up to 10 mm |

| 12 kW | up to 30–40 mm | up to 20–25 mm | up to 16–20 mm |

| 20 kW | 50 mm and above | 30–40 mm | up to 30 mm |

3.2 Beam Delivery and Cutting Head

The fiber beam is transmitted through fiber-optic cables to the cutting head, where it passes through a collimation lens and focusing lens. The cutting head focuses the beam into a tiny spot, typically below 0.15 mm, and directs it through a nozzle aligned with the assist gas flow.

Industrial cutting heads usually feature:

- Auto-focus lens systems

- Capacitive height sensing (±0.01 mm)

- Anti-collision design

- Lens cooling and contamination monitoring

- Automatic nozzle cleaning and calibration

A high-quality cutting head is critical for stable cutting above 6–8 kW, especially in stainless steel and aluminum.

3.3 CNC Motion System and Machine Frame

An industrial laser cutter combines the laser optics with a high-precision motion system. Typical characteristics include:

- Heavy welded and annealed machine bed

- High-precision rack & pinion or linear motor drive

- Dual servo drives on the gantry

- Precision linear guide rails

Key performance parameters:

- Positioning accuracy: ±0.03 mm

- Repeatability: ±0.02–0.03 mm

- Acceleration: 1.0–4.0 G depending on the model

Fast acceleration is especially important for parts with many corners and small radius features. High-end models such as GA3 series can deliver very high dynamic performance for thin sheet metal production.

3.4 Assist Gas System: O₂ / N₂ / Air

Assist gas blows molten material out of the kerf and strongly influences edge quality and speed:

- Oxygen (O₂) — for carbon steel, supports oxidation and fast cutting

- Nitrogen (N₂) — for stainless steel and aluminum, produces bright, oxide-free edges

- Air — low-cost alternative for thin stainless and carbon steel

Industrial systems often integrate gas boosters, automatic gas switching, and real-time pressure monitoring to ensure consistent performance and low operating costs.

4. Types of Industrial Laser Cutting Machines

4.1 Standard Sheet Fiber Laser Cutters (3015 / 4020 / 6020)

The most common industrial systems are flat sheet fiber laser cutters with working areas such as 3000×1500 mm and 4000×2000 mm. Typical GWEIKE models include:

- LF3015GA — dual exchange table, high-speed production

- LF4020GH — large-format, high-power system

- LF3015LN — cost-effective entry-level industrial cutter

Typical applications:

- Metal furniture and shopfitting

- Electrical cabinets and power distribution enclosures

- Mechanical parts and machine frames

- Stainless steel products and kitchen equipment

- Signage and architectural panels

4.2 Tube and Sheet Combination Machines

Combination machines integrate sheet cutting with tube and profile cutting in a single platform. These systems are ideal for manufacturers that process:

- Square and round tubing

- Rectangular sections

- Angle and channel profiles

- Sheet components for brackets and plates

A tube + plate laser cutter can significantly reduce the number of machines and operations needed for frame fabrication and structural weldments.

4.3 Heavy Plate and Ultra-High-Power Systems (15–30 kW)

For shipbuilding, construction steel, mining equipment, and heavy machinery, ultra-high-power fiber lasers are used to cut:

- 30–50 mm carbon steel

- 20–40 mm stainless steel

- Thick aluminum and alloy plates

These systems use advanced cutting heads, special nozzles, high-pressure gas systems, and heavy-duty machine frames to maintain stability and cut quality at very high power levels.

4.4 Fully Automated Laser Cutting Lines

For factories with high-volume, high-mix production, fully automated laser cutting lines are used. These may include:

- Automatic sheet loading and unloading systems

- Tower storage systems for multiple sheet types

- Robotic sorting and stacking of finished parts

- Integration with bending cells and welding stations

- MES connectivity for production planning and tracking

Such lines can operate with minimal human intervention, dramatically reducing labor cost and increasing throughput.

5. Metals and Thickness Capacity in Industrial Laser Cutting

Industrial fiber laser cutters are specifically designed for metals. The main materials include:

5.1 Carbon Steel

Carbon steel is the most commonly processed material. Fiber lasers cut it at very high speeds using oxygen or air. Typical applications include structural components, machine frames, brackets, and general fabrication.

5.2 Stainless Steel

Stainless Steel is widely used in food processing, medical equipment, architecture, and automotive. Nitrogen cutting produces bright, oxide-free edges that often require no secondary finishing.

5.3 Aluminum and Aluminum Alloys

Aluminum has high reflectivity, but modern fiber lasers handle it efficiently. With sufficient power (e.g. 6–12 kW) and nitrogen cutting, excellent edge quality and productivity can be achieved.

5.4 Brass and Copper

Brass and copper are more challenging due to reflectivity and thermal conductivity. However, with optimized parameters and proper cutting heads, fiber lasers cut thin to medium-thickness brass and copper safely.

5.5 Galvanized Steel and Coated Materials

Galvanized steel is widely used in HVAC, ducting, and structural applications. Laser cutting can process galvanized sheet efficiently with minimal edge contamination.

6. Cutting Quality and Process Control

Cutting quality is the main metric industrial customers care about. Good quality means smooth edges, small kerf, minimal dross, low taper, and stable repeatability. Four technical factors are especially important:

6.1 Laser Power and Beam Mode

High-power fiber lasers come in different beam modes:

- Single-mode — smaller focus spot, high energy density, best for thin stainless steel and fine-feature cutting

- Multi-mode — larger and more robust spot, ideal for thick plate cutting and general fabrication

For example, 6–12 kW single-mode lasers are excellent for ultra-high-speed thin stainless cutting, while 15–30 kW multi-mode lasers are better for very thick carbon steel.

6.2 Cutting Head Optics

Optics determine focus quality and thermal distribution. Professional cutting heads integrate:

- High-quality collimation and focusing lenses

- Advanced cooling and contamination control

- Auto-focus mechanisms

- Real-time piercing detection and protection

Dirty lenses or poor optical design will immediately reduce cut quality, especially in stainless steel and high-power operation.

6.3 Assist Gas Dynamics

Gas pressure, flow, purity, and nozzle design directly affect edge quality:

| Material | Gas | Typical Pressure (bar) |

|---|---|---|

| Thin stainless (0.8–2 mm) | N₂ | 18–22 |

| Thick stainless (>8 mm) | N₂ | 22–30 |

| Carbon steel | O₂ | 0.6–2.0 |

| Thin sheet (air cutting) | Air | 8–12 |

Nitrogen purity (often 99.999%) is critical for bright stainless edges and avoiding discoloration.

6.4 CNC Motion Accuracy

Even with the best laser source and optics, poor motion accuracy will ruin cut quality. Industrial machines focus on:

- High rigidity of the machine bed and gantry

- Precision machining of guideway mounting surfaces

- High-resolution servo motors and encoders

- Dynamic tuning of acceleration and jerk

High-end systems with linear motors achieve very high acceleration, ideal for parts that require thousands of short movements and high throughput.

7. High-Power Cutting Techniques (6–30 kW)

7.1 Nitrogen Fast Cutting for Stainless Steel

At 6–12 kW, nitrogen cutting of thin stainless steel enables extremely high feed rates while delivering mirror-smooth edges. For example, 3 mm stainless steel can be cut at tens of meters per minute, especially when combined with linear motor drives.

7.2 Oxygen Cutting for Carbon Steel

Oxygen supports an exothermic reaction with carbon steel. This allows high-speed cutting with relatively lower laser power. It is the standard process for mild steel fabrication, construction steel, and general manufacturing.

7.3 Air Cutting for Low-Cost Production

Air cutting has become popular for thin sheets (1–3 mm) because it dramatically reduces gas cost. With laser power above 6 kW, air cutting can achieve very competitive cut quality and speed on both stainless and carbon steel.

7.4 Thick Plate Cutting above 20 mm

For 20–50 mm carbon steel, high-power lasers (15–30 kW) use specialized cutting strategies, including:

- Multi-stage piercing with monitoring

- Slow-speed high-quality modes

- Optimized nozzle designs for stable molten metal removal

- Careful parameter tuning for edge straightness

8. Industrial Applications and Use Cases

8.1 Electrical Cabinets and Power Distribution

Laser cutting is ideal for electrical cabinets, switchgear, and power distribution enclosures. It allows precise cutouts, doors, ventilation features, and mounting patterns with minimal distortion.

Benefits:

- High dimensional accuracy and repeatability

- Clean edges suitable for powder coating

- Easy integration with bending and welding processes

8.2 Automotive and Vehicle Manufacturing

Automotive manufacturers use laser cutting for exhaust components, battery trays, brackets, heat shields, and structural parts. Fiber lasers support high-speed production of complex geometries with strict tolerance requirements.

8.3 Elevator Panels and Architectural Stainless Steel

Elevator manufacturers and architectural companies require flawless stainless surfaces. Nitrogen cutting produces bright, oxide-free edges that match high aesthetic standards.

8.4 Metal Furniture and Interior Decoration

For metal furniture, shelving, displays, and decorative panels, laser cutting eliminates the need for tooling and allows unlimited pattern design.

8.5 HVAC and Ducting

HVAC manufacturers process large volumes of galvanized steel and thin stainless. Fiber laser cutting is well-suited for flanges, mounting plates, brackets, and duct components, especially when combined with auto nesting.

8.6 Job Shops and Contract Manufacturing

Job shops rely on flexible, fast-turnaround equipment. Industrial fiber lasers allow them to handle a wide range of customer requirements, from prototypes to mass production, without extra tooling.

9. Industrial Safety, Maintenance, and Uptime

For industrial buyers, uptime is as important as cutting speed. Proper maintenance and safety controls ensure long-term stable operation.

9.1 Daily Maintenance

- Inspect and clean protective lenses

- Check nozzle condition and concentricity

- Verify assist gas pressure and leaks

- Remove slag and clean the cutting table

9.2 Weekly Maintenance

- Lubricate mechanical components (if required)

- Check chiller temperature and flow stability

- Inspect fiber connectors and cables

- Review cutting head log data and alarms

9.3 Monthly Maintenance

- Deep clean optical paths and check lens condition

- Perform calibration and accuracy checks

- Review servo, drive, and CNC diagnostic logs

- Inspect machine bed and guideways for wear or damage

9.4 Safety Requirements

- Use proper class-4 laser safety measures

- Enclose the cutting area where possible

- Install appropriate exhaust and filtration systems

- Provide operators with training and protective equipment

- Ensure emergency stop and interlock systems function correctly

10. How to Choose the Right Industrial Laser Cutting Machine

Choosing the right industrial system requires evaluating materials, thickness ranges, part mix, automation needs, and budget.

10.1 Select Laser Power Based on Thickness

| Main Application | Recommended Power |

|---|---|

| 1–6 mm sheet metal | 3–6 kW |

| 6–16 mm carbon steel, mixed thicknesses | 6–12 kW |

| Heavy plate 20–40 mm | 15–30 kW |

10.2 Choose Cutting Bed Size

| Format | Typical Use |

|---|---|

| 3015 (3 × 1.5 m) | Standard sheet metal jobs |

| 4020 (4 × 2 m) | Larger industrial parts and panels |

| 6020 / 8025 | Heavy plate and large structural parts |

10.3 Define Automation Requirements

- Single table — suitable for low-volume or prototype work

- Dual exchange table — standard for most production factories

- Automatic loading/unloading — for high-volume, multi-shift operations

- Storage towers and sorting robots — for fully automated lines

10.4 Evaluate CNC and Software

- Controller brand and reliability

- Nesting software capabilities and material utilization

- Support for barcodes, ERP/MES integration, and job tracking

- Remote diagnostics and service connectivity

10.5 Consider Total Cost of Ownership (TCO)

TCO includes not just purchase price, but:

- Electricity consumption

- Assist gas costs (O₂, N₂, air)

- Lens, nozzle, and consumable replacement

- Maintenance and spare parts

- Operator training and labor

Fiber lasers typically offer lower TCO than CO₂ or plasma over the lifetime of the equipment, especially for high-volume production.

11. Industrial Laser Cutter Price Range and ROI

11.1 Typical Price Ranges (Reference)

- Entry-level industrial fiber (1–3 kW): approx. $12,000–$28,000

- Mid-range 6–12 kW production systems: approx. $30,000–$70,000

- High-power 15–30 kW systems: approx. $80,000–$180,000+

- Fully automated cutting lines: approx. $150,000–$500,000+ depending on configuration

Actual pricing depends on configuration, power, automation level, and regional support. However, many manufacturers recover their investment in 1–3 years thanks to:

- Higher productivity and shorter lead times

- Lower labor cost per part

- Reduced tooling and setup costs

- Lower scrap rates and rework

12. Industrial Laser Cutting FAQ

Q1. What power fiber laser is best for general sheet metal fabrication?

For most sheet metal job shops and OEMs, a 6–12 kW fiber laser offers the best balance. It covers 1–25 mm carbon steel, 1–12 mm stainless steel, and moderate aluminum thicknesses with high productivity.

Q2. Should I buy a 20 kW laser?

Consider 20 kW if you:

- Regularly cut heavy plate >25 mm

- Run multi-shift, high-volume production

- Need extreme piercing speed and maximum throughput

If you mainly cut 1–6 mm sheet, 6–12 kW is usually sufficient and more cost-effective.

Q3. Does nitrogen cutting cost more than oxygen or air?

Yes, nitrogen cutting is more expensive due to gas cost, but it delivers the highest edge quality and is required for stainless steel in many industries. Air cutting can reduce gas costs significantly for thin sheet applications.

Q4. Which is better: rack & pinion or linear motor?

Rack & pinion systems are cost-effective and suitable for most 3–12 kW applications. Linear motors offer higher acceleration and are ideal for thin sheet, high-speed production where every second counts.

Q5. What cutting size should I choose: 3015 or 4020?

3015 (3 × 1.5 m) is the most common format and covers the majority of standard sheet sizes. 4020 (4 × 2 m) is recommended if you process larger plates or need more layout flexibility for nesting.

Q6. How important is automation for an industrial laser system?

For high-volume manufacturing, automation is critical. Dual exchange tables, automatic loading/unloading, and tower systems can dramatically reduce labor, improve utilization, and stabilize production.

Conclusion: Why Industrial Fiber Lasers Are the Future of Metal Fabrication

Industrial laser cutting machines combine high-power fiber lasers with precision motion control, advanced optics, and digital automation to deliver unmatched productivity, flexibility, and quality in sheet metal fabrication.

By choosing the right power, bed size, and automation level — and by working with an experienced supplier — manufacturers can dramatically reduce costs, shorten lead times, and expand their capabilities in a highly competitive market.

Looking for an Industrial Fiber Laser Cutting Machine?

GWEIKE provides a full range of industrial fiber laser cutters from entry-level 3 kW systems to high-power automated cutting lines. Explore our core models for sheet metal fabrication:

View LF3015GA View LF4020GH Small laser cutting machine