Best Laser Cutter and Engraver 2025 — Clear Picks for Every Need

In 2025, lasers are faster, cleaner, and more precise. The right machine lifts part quality, output, and ROI. At GWK Laser, we build fiber sheet cutters, tube cutters, sheet–tube combos, automation cells, 3D robot systems, and CO₂ cutters for non-metals.

How We Picked & Why It Matters

It isn’t about the cheapest machine—it’s about the right one. We consider what you cut, how thick, how much you need to produce, the space and safety requirements, your budget and true running costs, and the service backing the purchase. Get the fit right and you’ll see cleaner edges, quicker jobs, and safer work.

Top Picks 2025 (12 Models) — Expanded

A) Sheet Metal (Fiber)

GH Series — Thick Plate & Max Output

Best for

· Heavy machinery, ship/building steel, big fabricators

· Long shifts, 24/7 lines

· Parts that need both speed and edge quality

- Ultra-high power (up to 30 kW class) for thick steel and alloy

- Enclosed cabin + dual swap table → low idle time

- Rigid frame keeps speed and accuracy at high power

- Stable cut on stainless, carbon steel, aluminum

- Fast pierce modes for thick plate

- Strong fume & dust control

GA Ⅲ Series — Stable TCO

Best for

· Auto parts, general steel work, job shops

· Buyers who want long-term cost control

· Teams that value uptime more than peak power

- 5-year warranty lowers risk, builds trust

- Enclosed + dual swap table for steady output

- Balanced speed and cut quality for daily jobs

- Easy service access, simple upkeep points

- Good energy use at mainstream powers

LN Series — Thin–Medium Sheets

Key strengths

- Single table → compact footprint

- Quick setup and changeover

- Fast on thin to medium gauges

- Low unit cost for short runs

- Easy to place in busy floors

Best for

· Contract shops with many SKUs · Cabinets, enclosures, hardware · Users upgrading from CO₂ to fiber

Options / notes

· Auto nozzle height, breakpoint resume, light automation

P Series — Compact Fully Enclosed

Key strengths

- Whole cover for safety, dust, and noise

- Small size fits tight or urban sites

- Clean look for demo rooms or schools

- Good edges on thin–medium sheets

- Simple HMI for new operators

Best for

· Small factories, labs, training centers · Sites with strict EHS rules · Night runs near office areas

Options / notes

· Fume packs, camera view, barcode job load

SL Series — Extra-Long Parts, Ground-Rail

Key strengths

- Ground-rail for long-format stability

- Handles heavy sheets and large fixtures

- Smooth motion on long cuts

- Lower thermal drift on long passes

- Great for thick frames and long channels

Best for

· Construction steel, buses, trailers, big panels · Long beams, long bracket nests · Harsh shop floors

Options / notes

· Side unload zones, split nests, crane-friendly layout

B) Tube & Profile (Fiber)

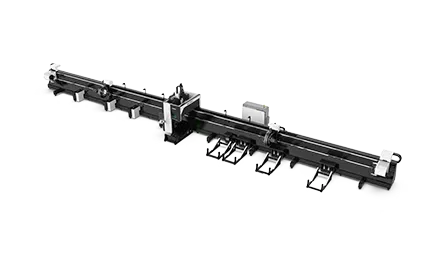

T3 / T3L — Long Tubes, 3-Chuck Stability

Best for

· Furniture, gym gear, frames, racks · Long rails, ladders · Shops that need tube accuracy every day

Options / notes

· Auto loading, seam finding, bevel (where supported)

Key strengths

- Three-chuck layout supports long stock and odd shapes

- Better concentricity, less whip at speed

- Strong clamping on thin and medium walls

- Smooth rotary for tight features

- Works on square, round, shaped tube

T4 — Big Diameter / Thick Wall (4-Chuck)

Best for

· Oil & gas, big frames, heavy vehicles · Thick-wall steel and large sections · Low scrap targets on costly stock

Options / notes

· Auto support rollers, tailing scrap control, bevel head (opt.)

Key strengths

- Four-chuck heavy-load clamping

- High torque for thick-wall cuts

- Steady feed on large OD stock

- Stable cut start/stop on heavy tubes

- Safer handling of long, heavy pieces

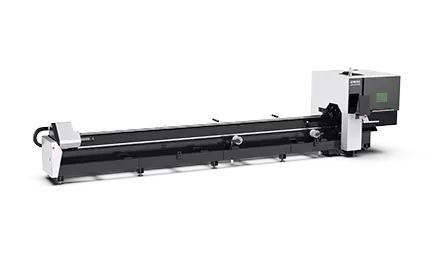

TM — General-Purpose Tube

Best for

· Job shops with mixed SKUs · Sub-contract tube cutting · Teams moving from saw/drill to laser

Options / notes

· Bundle loading, etch/mark, short-part catcher

Key strengths

- Good balance: speed, accuracy, price

- Handles most daily tube jobs

- Easy to train, easy upkeep

- Solid cut on steel, stainless, aluminum

- Great first tube line

T2 — Small-Tube Specialist

Best for

· Fitness gear, furniture, light frames, displays · Micro-frames and fixtures · Short-cycle repeat parts

Options / notes

· High-speed package, auto job queue, label print

Key strengths

- Tuned for small OD and thin walls

- Fast accel for small features

- Clean ends for fit-up and welding

- Low burr, good end quality

- Compact near bending cells

C) Combo / CO₂ / Automation

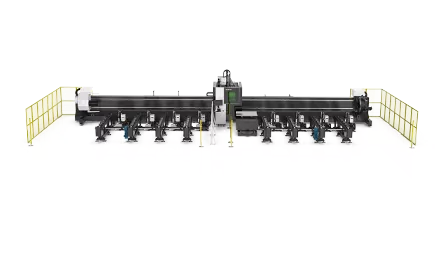

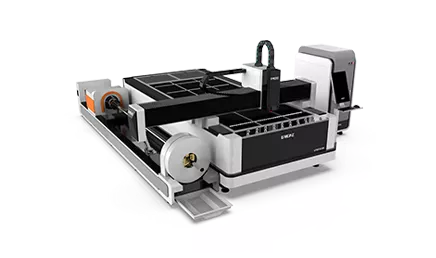

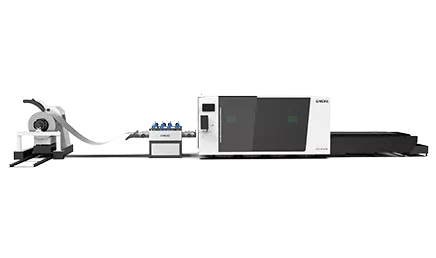

CNR / GCR / LNR — One Machine: Sheet & Tube

Key strengths

- Cuts sheets and tubes on one platform

- Saves floor space and CAPEX vs two lines

- One controller → easier training

- Fast switch between modes for small batches

- Great for many SKUs with low volume each

Best for

· New lines that need both sheet and tube · Mixed orders · SMBs growing into more SKUs

Notes

Pair with GAR if you need bigger sheets (3015/4020/6025)

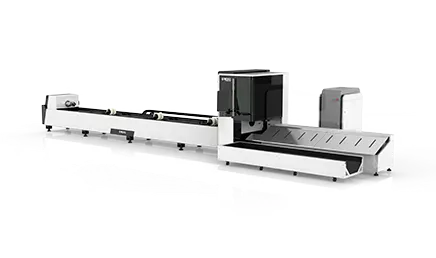

GAS — Auto Loading & Unloading

- Keeps cycle time steady and cuts handling

- Safer sheet moves; fewer scratches

- Helps night or low-touch shifts

- Frees staff for quality checks

Best for

· Repeat jobs and big batches · Lines with few operators · Plants pushing OEE gains

Notes

Works with towers/racks; supports barcode jobs

LC1390N (CO₂, Wood) — Mid-Format Non-Metals

- Very clean edges on wood, acrylic, fabric, leather

- Fine engraving and small text

- Stable frame for long runs

- Easy to learn; fast setup

- Good dust control; simple service

Best for

· Signage, décor, craft products · Teaching aids, display panels · Print shops adding non-metals

Options

· Honeycomb/blade tables, air-assist kits, camera align (opt.)

3) More Options (Quick List)

Sheet (Fiber): GA Series(mainstream high-performance) / E PRO(entry value) / SE(large flatbed) / LF1390 / LF0660(precision small-format) / LC Hybrid(metal & non-metal)

Tube (Fiber): TG(heavy-duty 3-chuck) / TE(economical)

Combo: GAR(bigger tables: 3015/4020/6025)

Automation: CPL3015B(coil-to-blank for thin sheet, high yield) / M Series (6-in-1)(cut / weld / clean / drill / bevel / mark)

3D & Surface: LF1800(3D robot cut) / M3015G(3D 5-axis) / Large 3D H-tube(H-beam & heavy profiles) / GKS-LC3008R(laser cladding)

4) Sheet & Tube Combined — Versatility at Its Best

CNR / GCR / LNR

cut sheets and tubes in one cell. You save space and cost, share parts and skills, and switch fast for small batches.

GAR (3015/4020/6025) adds larger tables while keeping tube ability.

Why it matters

- One machine, two missions

- Smaller footprint, higher OEE

- Lower CAPEX vs two lines

5) Automation & Flexible Manufacturing

GAS auto load/unload keeps cycle time steady and cuts handling.

CPL3015B runs coil-to-blank for thin sheet at high yield.

M Series (6-in-1) gives one flexible platform: cut / weld / clean / drill / bevel / mark.

6) Robot / 3D & Surface Engineering

LF1800

(3D robot) cuts complex curves on formed parts.

M3015G (3D 5-axis) reaches deep-drawn areas with multi-angle access.

Large 3D H-tube handles H-beam and heavy profiles.

GKS-LC3008R does fast laser cladding for repair and hardfacing.

7) CO₂ Laser Cutter Series — For Non-Metals

CO₂ is for non-metals: wood, acrylic, leather, fabric, paper, rubber. It gives clean edges, fine engraving, and stable 24/7 work.

Small-Format / Entry & Desktop

- LG6040N (Engraving) — modern design, great value; compact; bench-friendly; fine engraving on small parts.

- STORM600 (Wood) — Best Seller — stable wood cutting; small footprint; easy panel; fast daily start.

- LC6090 (CO₂) — HD camera for print-to-cut; ideal for stickers, printed acrylic/leather; higher placement accuracy.

- LG900N (Wood) — step-up work area; steady on wood/acrylic; good for small-to-mid signage.

Mid-Format / Mainstream General-Purpose

LC1390N (Wood) / LC1390 (CO₂) — both are stable non-metal cutters in the popular 1390 size for letters, light panels, teaching aids, wood & acrylic.

Large-Format / Full-Sheet Efficiency

- LC1325M (CO₂) / LC1325D (CO₂) — full-sheet jobs: furniture boards, large acrylic, props, acoustic panels. Add a side-by-side spec block (platform, guides/transmission, motion specs, options).

- LC1610N (CO₂, Dual-Head) — “two-in-one” output for repeat patterns: textile parts, leather, perforation, grilles. Great when you need more output without more floor space.

8) How to Choose (Fast Guide)

| Dimensions | Options / Remarks |

|---|---|

| Job type | SheetTube BothNon-metal |

| Thickness | Thin < 6 mmMedium 6–20 mm Extra thick |

| Size & layout | CompactLarge tables |

| Output | Dual tablesAuto loadCoil feed |

| Budget & ROI | SpeedUptimeYield → payback |

| Service | WarrantyTrainingParts lead time |

9) FAQ

Can CO₂ cut metal?

No. CO₂ here is for non-metals (wood, acrylic, leather, fabric, paper, rubber).

What power do I need?

Size for your thickest common job.

Do I need automation?

If loading time or labor is a bottleneck, yes.

Tube model to start?

TM for general work; T3/T3L or T4 for long or heavy tubes.

10) Conclusion

You don’t need every machine. You need the right one. Start with job type and thickness, then choose from our Top 12. If your work mix is wider, open More Options and match by scene.

Next step: tell us your main material, thickness range, and weekly volume. We’ll size the power, table, and automation to hit your ROI goal.